The

Science Notebook

Gilbert Chemistry - Part 10

The

Science Notebook

Gilbert Chemistry - Part 10

NOTE: This book was published in 1936 as a manual

to accompany several Gilbert Chemistry sets of the time.

While some of the experiments and activities here

may be safely done as written, a number of them use chemicals

and methods no longer considered safe. In

addition, much of the information contained in this book about

chemistry and other subjects is outdated and inaccurate.

Therefore, this book is probably best appreciated for

its historical value rather than as a source for current

information and good experiments. If you try

anything here, please understand that you do so at

your own risk. See our Terms

of

Use.

Pages 181 - End

GILBERT

CHEMISTRY 181

from this jar into one of the other two jars, being careful not to

allow any of the liquid to get into this jar. Figure 37.

Now seal the two iars containing the sprouted beans or peas and

allow them to stand for several days in the sunlight. Label

the one containing the carbon dioxide. Examine the jars from

time to time and notice that the plants in the jar containing the

carbon dioxide grow faster than those in the other jar. This

proves that carbon dioxide is essential to plant growth.

A

SIMPLE PHOTOCHEMICAL EXPERIMENT TO DETERMINE THE ACTIVITY OF THE

ENERGY OF THE SUN'S RAYS

EXPERIMENT 619 (Sodium

nitroprusside and thiourea purchased separately)

Four test tubes are numbered and placed in a rack so that equal

exposure to light may be secured.

In tube one is placed one-quarter of a test tube each of the three

solutions sodium nitroprusside, sodium bicarbonate, and

thiourea. In tube two is placed one-quarter of a test

tube each of the sodium nitroprusside and sodium bicarbonate

solutions only. In tube three is placed one-quarter of a

test tube each of the thiourea and sodium bicarbonate solutions

only. In the last tube one-quarter of a test tube of sodium

nitroprusside and one-quarter of a test tube of thiourea solution

are mixed.

the four tubes are then placed in the sunlight for from four to six

minutes. A blue color will form quickly in tube one and slowly

in tube four, number two will darken slightly, and tube three will

remain unchanged. The reaction will proceed in ordinary light,

but at a much slower rate.

The tubes are removed from the sunlight as soon as one and four are

distinctly blue, and one-quarter test tube of thiourea solution is

added to tube two. A blue coloration will take place quickly without

the aid of further exposure to light. One-quarter test tube of

nitroprusside solution is then added to tube three. The blue color

will not be formed in this case, showing that the sunlight does not

cause any change with thiourea in sodium bicarbonate solution.

182

GILBERT CHEMISTRY

The tubes are now placed in total darkness for a period of three to

six hours or more. Upon removal it will be noted that tubes

one two have changed to a deep crimson, tube four will be blue and

practically unchanged, while tube three will be colorless, although

all the necessary reagents for the reaction have been present for

several hours.

If one-quarter of a test tube of sodium bicarbonate solution is

added to tube four, the blue color immediately takes on a purplish

tint and if kept in the dark the color will be decidedly red after

about one-half hour, showing that the tube "stored darkness" even

though it was not apparent, as in tubes one and two, until the

sodium bicarbonate addition.

All the tubes are then re-exposed to sunlight and the blue

coloration will immediately form in each, since all the reactants

are now present in each tube. Another period of darkness will

bring the red, etc., until finally the active ingredients are

decomposed, due to side reactions. If too long exposures to

sunlight are avoided after the blue color is produced, the reaction

may be reversed 12 to 20 times. If the solution is placed in a

completely filled, sealed container, the change blue to red will

fail to take place after several times, showing that the presence of

air is necessary, probably for the spontaneous re-oxidation of the

iron previously reduced by the action of the sunlight.

The solutions required are: one-half oz. of freshly prepared 0.5%

sodium nitroprusside (to be kept in an opaque bottle;) one-half oz.

of saturated sodium bicarbonate; and one-half oz. of 0.5% thiourea.

"COLD

LIGHT," OR LIGHT BY CHEMICAL ACTION

EXPERIMENT 620-A demonstration of

"chemiluminescence"

One of the most beautiful and striking demonstrations for laboratory

or lecture work is that of chemiluminescence or “cold light."

Certain chemical reactions, usually ones involving the oxidation of

an organic compound, result in the development of light without

other visible reaction. Even heat, which is usually associated

with light of any kind, is noticeably absent.

This phenomenon of chemiluminescence

has long been known, but has not previously been employed

extensively because of difficulties encountered in the available

reactions. These were complex and dangerous, produced only a

limited luminescence, or required reagents not readily obtainable.

But now three-aminophthalhydrazide has been made available which

overcomes all of these objections. The reaction is simple,

safe, and develops light of intense brilliancy.

LUMINOL

The name "luminol" has recently been applied to this compound in

place of its chemical name for convenience, to associate with it the

property of luminescence.

The demonstration requires only the oxidation of luminol in dilute

alkaline solution with three per cent alkaline hydrogen peroxide and

a second oxidizing agent. All four compounds are necessary in

the solution to obtain the strongest radiation. Almost

GILBERT

CHEMISTRY 183

innumerable variations can be used in the actual procedure, from the

mere mixing of the required chemicals to very elaborate

displays. A few of the simpler methods are given to serve as guides.

For small audiences or laboratory demonstration, the flask method is

the most satisfactory. In a two-liter long-necked flask, a

small quantity of luminol on the point of a knife blade is dissolved

in a test tube full of five per cent sodium hydroxide and diluted to

two quarts with water. In a similar flask, two knife blade

portions of potassium ferrocyanide is dissolved in water, a test

tube full of three per cent hydrogen peroxide added and diluted to

two quarts with water. When both solutions are ready and the

room is darkened, one flask is grasped in each hand and the contents

of them poured simultaneously through a funnel into a six-liter

flask. The reaction starts as soon as the liquids mix in the

funnel. After the initial development of the light has begun,

the flask is swirled and a small quantity of solid potassium

ferricyanide added. The brilliance is increased and can be

still further intensified by the gradual addition of five percent

sodium hydroxide. At the concentrations given, the original

light intensity is small, but the increased brilliance obtained by

the addition of further reagents is very beautiful.

For demonstration to larger audiences, it is more convenient to use

a large jar containing about 14 quarts of water. In a small

flask is dissolved one spoon measure of luminol in five test tubes

full of five per cent sodium hydroxide, and in a second flask, 25

spoon measures of potassium ferricyanide in five test tubes full of

three per cent hydrogen peroxide. To indicate more clearly the

lack of heat in the reaction, the solution may be poured

simultaneously over a cake of ice which has been floated in the

water. The solutions should be allowed to mix in concentrated

form on the ice before being diluted with the surrounding

water. After the reaction mixture has diffused throughout the

water, the solution is stirred vigorously with a glass rod and

further potassium ferricyanide or alkali or both added as desired.

A very beautiful display may be prepared by means of two fine sprays

which are made to interact some distance above the lecture

table. Each spray of humidifier is connected to a compressed

air source and to one of the stock solutions previously

mentioned. Care should be taken that the spray guns are

operating at the same rate. By variation of the stock solutions, the

resulting mist can be changed from a hardly visible cloud to a

brilliant fountain resembling a display of fireworks.[*]

[*] The reagent "luminol" may be purchased' from the Eastman Kodak

Company. Rochester, N. Y.

[184]

PART IV

Electro-Chemistry

Before we discuss the part electricity takes in chemistry we must

first know a little something about electricity. Electricity, like

heat, is a form of energy. About 100 years ago very little was known

about the role that electricity played in chemical reactions.

Today matters are quite different. Electricity and chemistry

are very closely related, many large and important industrial

concerns are engaged in manufacturing materials involving the use of

electro-chemical reactions.

Today chlorine gas and caustic soda are manufactured by passing an

electric current through salt water. From the chlorine gas we

obtain bleaching powder. Metals are extracted from their ores

by passing a current through their molten or fused salts.

Nickel-plating, copper-plating and gold-plating are done by passing

a current through a solution containing salts of these metals.

The success of these important industries and many others is based

on the fact that electricity possesses the power of decomposing

chemical compounds.

On the other hand, we can show the relationship between chemistry

and electricity in another way. We have already said that

electricity is a form of energy. Now, in most chemical

reactions, heat is liberated as the form of energy. However,

under proper conditions, the energy of certain chemical reactions is

liberated in the form of electricity. For example, if we put a

copper plate and zinc plate in a solution containing an acid and

connect the two plates with copper wires we find that a current of

electricity is produced. A reaction takes place in which

electricity in the form of energy liberated. Use is made of

this fact in the manufacture of the different types of electric

cells and batteries. Batteries are simply cells connected

together in series in order to produce a stronger current.

There are several types of cells, all of which come under two

classes, namely, the primary cells, which include both the dry and

wet cells, and the secondary cell or storage battery, as it is

called.

Finally, we will mention a third relationship of electricity to

chemistry. That is, the part electricity plays in furnishing heat to

produce chemical change. A good example of this is the

manufacture of graphite from carbon by means of the electric

furnace. Also the manufacture of calcium carbide for the

production of fertilizers, of nitric acid from nitrogen in the air,

and many other important industries depend upon the heat generated

by the electric current for their success.

Before we discuss any of the different types of cells we will first

consider the parts that go to make up a primary cell. These are,

first, the jar which holds the solution and the elements; second,

the solution of electrolyte, as it is commonly called; third, the

cathode or negative electrode, which is usually made of the element

zinc; and, fourth, the anode, or positive electrode, which is

usually the element carbon.

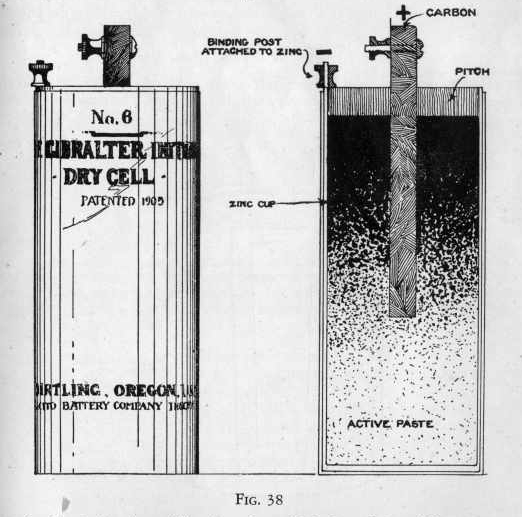

THE

DRY CELL AND HOW IT IS MADE

The dry cell is a very common type of cell and millions of them are

used for bell, telephone and other purposes. The jar of the dry cell

consists of a cup of sheet zinc which serves as the negative

electrode (Figure 38.) A binding post is fixed at the top of

this cup. The electrolyte in the dry cell consists of an

active paste which consists usually of one part of zinc chloride,

one part of zinc oxide, one part of ammonium chloride or sal

ammoniac, three parts of plaster of Paris, two parts of manganese

dioxide and one part of water, all by weight.

GILBERT

CHEMISTRY 185

The cell is prepared as follows: the zinc cup is filled to within

one~half inch of the top and a carbon rod containing a binding post

on the upper end is pushed down into the paste to within an inch of

the bottom. Melted pitch is then poured over the paste until

it is even with the top of the cup. The pitch is then allowed

to cool, and the cell is ready for use. It is only when you

close the circuit, that is, connect the two binding posts with a

wire, that you start chemical action within the cell. When the

circuit is open the chemical action stops.

HOW

THE DRY CELL WORKS

After the cell is made and copper wire is attached from the carbon

post to the zinc post a current of electricity passes through the

wire. This is due to action of the active paste upon the zinc

electrode. When the circuit is opened, that is, when the

carbon and zinc posts are disconnected, the action stops.

Now the chemical action which takes place within the cell is as

follows: The ammonium chloride and water react to form hydrochloric

acid which attacks the zinc. The zinc goes into solution in

the form of positive ions, which are atoms or groups charged

electricity. When this happens the zinc electrode assumes an

electro negative condition. The positive zinc ions unite with

the negative chlorine ions of the hydrochloric

186

GILBERT CHEMISTRY

acid to form zinc chloride with the formation of positive hydrogen

ions. Now, the positive hydrogen ions move to the carbon

electrode where they lose their charge and become gaseous

hydrogen. Therefore, when the circuit is closed the chemical

action, which takes place, keeps the zinc pole or cathode negatively

charged and the carbon pole or anode positively charged. The

flow of electricity is always from the negative zinc pole to the

positive carbon pole through the solution, and from the positive

carbon pole to the negative pole through the wire.

You might ask the question, What happens to the hydrogen gas when

chemical action takes place within the cell? The hydrogen gas

as fast as it is formed at the carbon electrode is oxidized to water

by oxygen from the manganese dioxide. This brings up the

phenomenon known as polarization. By polarization is meant the

cutting down of an electric current, due to the lowering of

potential between the carbon and zinc poles. Polarization in a

cell is caused by formation of bubbles of hydrogen gas clinging to

the carbon electrode, thereby producing less surface. To

prevent this, manganese dioxide is used, which, as already stated,

oxidizes the hydrogen gas to water.

THE

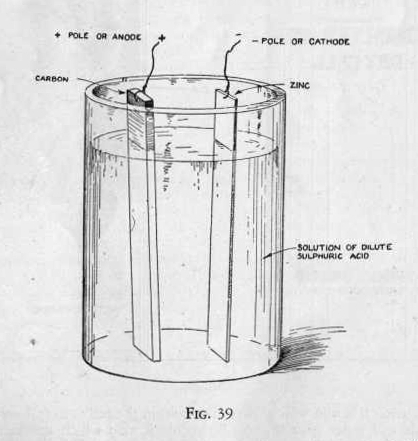

WET CELL

The wet cell or other type of primary cell is very similar to the

dry cell. The electrolyte instead of being a paste, as in the dry

cell, is a solution. The positive and negative electrodes are of

carbon and zinc or of copper and zinc. (Figure 39.) The

principles involved in the formation of a current due to chemical

action in the wet cell is the same as that in the dry cell although

there are several types of wet cells.

GILBERT

CHEMISTRY 187

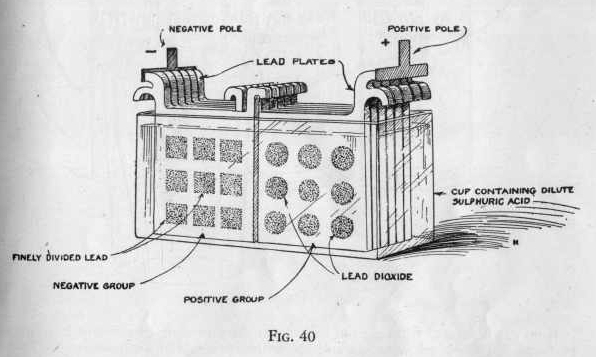

THE

STORAGE BATTERY

The second type of electric cell or storage battery is a little more

complicated than the dry or wet cell. The storage battery consists

of a number of secondary cells (Figure 40). It is used largely

for running electric power plants, electric automobiles, telephone

and telegraph work, etc.

The storage battery does not generate a current of electricity like

a primary cell by a direct chemical action. It is charged by a

current of electricity, after which it will deliver a current

until the cell is run down. The chemical action taking place

when the electricity is discharged is much more complex in this type

of cell, so that we will not go into a discussion of it.

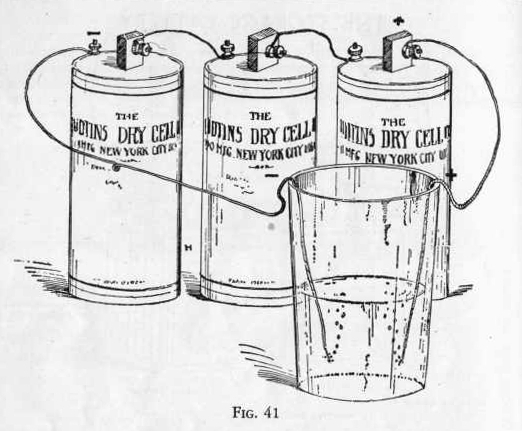

EXPERIMENT 621 - How to test a

battery of dry cells

if you have two or three dry cells around the house and wish to test

their strength, perform the following experiment with them:

Connect the cells together in series as shown in Figure 41 by

attaching small pieces of copper wire to the carbon binding post of

one cell and zinc binding post of the other cell. (Figure 41.)

Now connect a longer piece of wire to the free carbon post and

another long piece to the free zinc post. Clean the ends of

all the copper wires using with a knife blade.

Now dissolve two teaspoonfuls of sodium chloride (table salt) in a

tumbler two-thirds full of water and put the ends of the copper

wires, which should be clean, in the solution. Notice whether

bubbles of gas appear on the ends of the wires in the

solution. By setting up the same number of new cells in the

same manner and comparing the amount of gas produced with that

produced from the old cells you can tell whether the old cells are

of sufficient strength to be of value an performing the following

experiments.

188

GILBERT CHEMISTRY

If no gas is formed from the old cells when the preceding experiment

is accurately performed, the cells are worn out and you will have to

obtain some new cells. Two or three dry cells connected in series

will give you sufficient current for performing most of the

experiments as outlined.

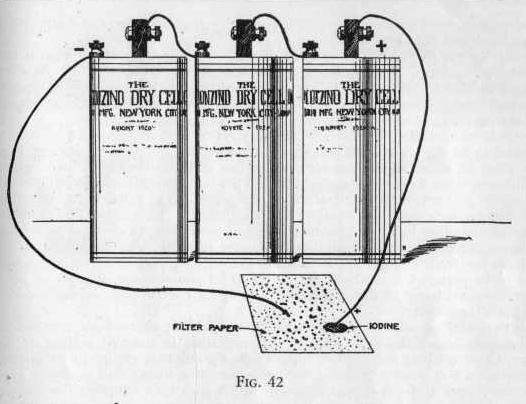

EXPERIMENT 622 - How to determine

the positive or negative wire

Connect two or three dry cells together in series as in Experiment

621. Now moisten a piece of filter paper with a little sodium

iodide solution and place the ends of the wires from the battery

about one-quarter inch apart on the paper (Figure 42). Notice

that the spot where one of the wires touches the paper becomes

brown. Also notice that this is the wire connected to

the positive or carbon pole.

What really happened was this: When you touched the ends of the

wires from the battery to the paper containing sodium iodide

solution you simply closed the circuit and a current of electricity

flowed from the positive carbon electrode to the negative zinc

electrode, at the same time decomposing the sodium iodide. The

iodine of sodium iodide being in the form of negative ions is

attracted to the positive wire, where they lose their charge and

become atomic iodine, thereby producing a reddish brown spot. This

is a very convenient way of telling what is the positive and

negative wire of any source of electricity.

EXPERIMENT 623 - Another way to

tell the positive and negative wires

Put two measures of potassium nitrate and two drops of

phenolphthalein in a test tube one-quarter full of water. Shake

thoroughly until all the solid is dissolved. Now moisten a piece of

filter paper about one inch square with some of this solution and

test the paper the same way you did in the preceding experiment.

Notice this

GILBERT

CHEMISTRY 189

time that the spot where one of the wires touches the paper becomes

red. Also notice that this wire is the wire connected to the

negative zinc binding post and is therefore the negative wire.

The potassium ions of the potassium nitrate being positively charged

are attracted to the negative copper wire, where they lose their

charges and become atomic potassium. Atomic potassium, being a

very active substance, instantly unites with the water to form a

base potassium hydroxide, which turns the phenolphthalein red.

EXPERIMENT 624 - How to show the

direction of a current

Dissolve eight measures of nickel ammonium sulphate in a tumbler

one-third full of water.

Now connect two or three dry cells in series as shown in Experiment

621 and put the ends of the wires leading from the positive and

negative poles of the battery into the nickel solution. Notice

that very soon the wire attached to the negative pole or electrode

is coated with metallic nickel or is being nickel-plated.

Now disconnect the two wires from the battery and attach the wire

which was plated with nickel to the positive carbon pole and the

other wire to the negative zinc pole. Put the ends of the

wires again in the solution. Notice that the nickel is soon

dissolved from the plated wire and is deposited on the other wire

which is attached to the negative pole.

This proves that the current always flows from the positive pole to

the negative pole and that the metal deposited always follows the

direction of the current.

ELECTROPLATING

The very simple process of transferring metal from one object to

another by chemical and electrical means is called electroplating.

All of the silverware in use is plated

190

GILBERT CHEMISTRY

by the same process you are going to use. By this method

objects are copper-plated, silver-plated and

gold-plated.

Besides its use in plating, the process is used in the purification

of certain metals. Copper, for example, is separated from its

impurities in this manner. At a recent chemical exhibit in New

York there was placed on exhibition a slab of copper five feet

square and six inches thick which had been purified not by removing

impurities from the copper, but by removing the copper from the

impurities.

In electroplating, the electrolyte or bath always consists of a

solution of the salt of the metal to be deposited or plated on the

object. Now, as to the action which takes place when an object

is electroplated, let us first consider the nature of solutions of

metallic salts when a current is passed through the solution.

Salts are made up of metallic elements and non-metallic elements or

groups. When in solution the metallic elements become ions and

have positive electric charges. The non-metallic elements or

groups on the other hand also become ions and have negative

charges. Now suppose we pass a current through a solution of

copper sulphate. The metallic copper ions which are positively

charged are attracted to the negative pole to which is attached the

object to be plated. On reaching the object to be plated the

copper ions lose their charge, become atomic or metallic copper and

as such are deposited in a smooth thin layer upon the object.

The non-metallic sulphate groups which are negatively charged are

attracted to the positive pole to which in the case of

copper-plating is attached a sheet or bar of copper. Upon

reaching the positive copper pole the sulphate groups lose their

charge, become molecular sulphate, having the properties of a strong

acid grouping and dissolve the copper to form copper sulphate which

goes into solution. The amount of copper which goes into solution in

this way is exactly equal to the amount of copper which is deposited

upon the object to be plated. You can see, therefore, that the

concentration of the copper sulphate solution is always the same as

long as there is any copper left at the positive pole.

The preceding action may be expressed a little more clearly in the

form of an equation, thus:

| Salt

|

electricity = |

metal (of salt)

goes to the object to be

plated (cathode -) |

non-metal (of salt)

goes to the metallic

plate (anode +)

|

By using different kinds of salts and plates of different metals we

can plate with almost any metal, although some metals plate easier

than others.

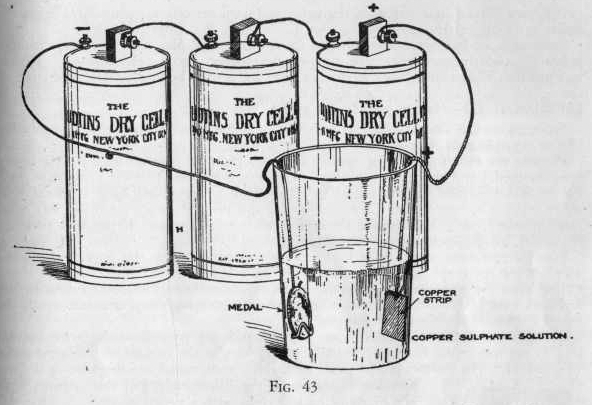

EXPERIMENT 625 - How to

copper-plate

If you have any medals which you wish to copper-plate, proceed as

outlined in this experiment. lf not, use a nail, or other iron

object.

The object to be plated must always be cleaned of oils, grease or

varnish. This can easily be done by boiling the object in vinegar or

a solution of sodium carbonate for several minutes. When

cleaned the object must never be touched with the fingers, for if it

is a film of grease will be left and the plating will not stick to

the surface.

Dissolve one spoonful of copper sulphate in a tumbler half full of

water. Now, using two or three dry cells connected up in

series as outlined in previous experiment, attach the medal or iron

object to be copper-plated to the wire from the zinc pole or

negative wire in the manner illustrated (Figure 43.) To the

wire from the carbon or positive pole of the battery attach the

copper strip.

Now immerse the copper strip and the medal in the copper sulphate

solution, being sure that the medal to plated is below the surface

of the solution. Do not allow the copper strip and medal to touch.

GILBERT

CHEMISTRY 191

In a few minutes you will note that the medal is covered with a

deposit of copper. leave the medal in the solution until an

even coat is deposited. This should take from 10 minutes to

one hour, depending upon the size of the object and the strength of

the solution.

To give the medal a bright finish, rub it lightly with an ordinary

pencil eraser.

EXPERIMENT 626-How to nickel-plate

The object to be nickel-plated must be free of oil, grease and

varnish. This can be done by boiling it in vinegar or a

solution of sodium carbonate.

Dissolve one spoonful of nickel ammonium sulphate in a tumbler half

full of water. Now attach the iron, copper or brass object to

be nickel-plated to the negative wire and an iron nail to the

positive wire. Immerse these in the solution and notice that soon

the object attached to the negative wire which goes to the zinc post

is covered with a coating of nickel.

ELECTROTYPING

Electroplating with copper has been taken advantage of in the

printing and publishing industry. Here it is called

electrotyping. This process consists in making a mold of wax or

plaster of Paris and the impression of the type of a book made by

pressing the mold against the type. The wax is then dusted

with graphite, which is a good conductor of electricity. It is

then connected to the negative pole of a battery and immersed in a

copper solution. The positive pole is a sheet

of copper.

When a suitable thickness of copper is deposited on the impression,

the thin sheet of metal is removed from the wax and "backed," that

is, the reversed side is filled with a low melting substance such as

solder or lead.

192

GILBERT CHEMISTRY

It is now affixed to a rotary, or flat press and used directly for

printing. Besides its use in printing, this process may be used for

making duplicates of medals. Practically all books are now

printed from electrotype plates. Without electrotype plates it would

be necessary to set up new type every time a new edition oi a

book was printed. This would take much more time and would be

much more expensive.

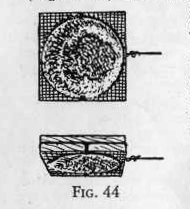

EXPERIMENT 627-How to reproduce a

medal

Secure a medal, one as small as possible, or some foreign coin which

you would like to reproduce in copper.

Prepare the molding wax by cutting a square piece of paraffin wax a

little larger than the medal and about one-eighth of an inch in

thickness. The wax may be molded flat by warming slightly and

kneading it with the fingers. Now hold it under cold water

until it becomes hard. Clean the medal and press it down upon

the wax with considerable force. Then remove the medal with a

knife point. If the wax sticks to the metal, oil the medal

very, very slightly.

Now scrape some graphite or lead from a soft pencil upon the

impression in the wax and rub the graphite to a fine finish with the

brush included in the set. lt is essential to give the

impression a compact and smooth surface, therefore, rub with the

brush as long as possible, even 15 minutes. Add more graphite if

necessary until the whole impression is black and shining.

Set up two or three cells in series and attach the wire from the

negative zinc post to the wax mold, making contact from the wire to

the surface of the impression. (Figure 44.) The contact is

made by making a channel from the wire to the impression as shown in

the illustration. Fill this channel with graphite and pack it tight

with a pencil point.

To the other wire from the positive carbon post of the battery

attach the copper strip. Now place the wax mold and the copper

strip about one inch apart in a tumbler containing a solution of

copper sulphate. The solution of copper sulphate is made by

dissolving one spoonful of copper sulphate in a tumbler half full of

water.

Allow the current to pass through the solution for several hours -

over night, if necessary - and examine the wax mold carefully from

time to time and notice that the copper-plate gradually creeps

across the impression.

When the process is complete and you have a thin sheet of copper

deposited on the impression, remove the wax mold from the solution,

wash it with water and then remove the wax by melting it in a tin

cover. The copper-plate then produced is an exact reproduction of

the medal and can be preserved by pasting it on a piece Of

cardboard.

You may nickel-plate the copper reproduction by placing it in a

solution of nickel ammonium sulphate as explained in the experiment,

"How to nickel-plate."

EXPERIMENT 628 - How to make a

bronze statue from a plaster cast

This is a very interesting experiment in electroplating.

Obtain a small white unpainted plaster statuette or cast and be sure

that it is small enough to fit into a tumbler or pint jar.

Now paint the statuette with a little linseed oil or quick drying

varnish and allow the oil to dry thoroughly. This makes the

statuette waterproof and forms a skin upon which the powdered

graphite will stick. When the oil is dry brush the statuette

with

GILBERT

CHEMISTRY 193

powdered graphite from your lead pencil. Brush until the

surface is smooth and black.

Set up two or three dry cells in series and wind the end of the wire

from the negative zinc post around the statuette. Attach the

copper strip to the wire from the positive carbon post. Now

place the statuette and copper strip in a copper sulphate solution

made by dissolving one spoonful of copper sulphate in a glass full

of water. Allow the statuette to remain in the solution until

it is evenly coated with copper. This is best done by leaving it to

stand over night.

lf you wish to nickel-plate the bronze cast, simply place it in a

solution of nickel ammonium sulphate, as explained in the experiment

on nickel-plating.

ETCHING

BY MEANS OF ELECTRICITY

Pretty pattems or designs may be duplicated on sheet copper or steel

very easily by means of the electric current. The designs will

have the appearance of being etched.

EXPERIMENT 629 - How to etch

on copper.

Take the copper strip and dip it into hot paraffin. When it is cold,

trace the design you want and then with a toothpick remove the

paraffin along the tracings. Also scrape off the paraffin

where connection is to be made with the wire and copper strip.

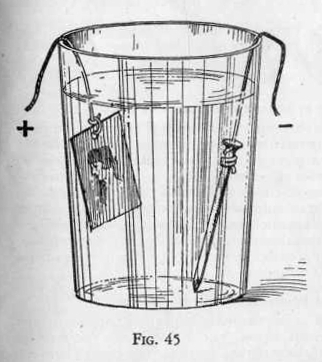

Now connect two or three dry cells in series and attach the wire

from the positive carbon post to the copper strip to be etched.

(Figure 45.) To the wire from the negative zinc post attach a

bright nail or other object of iron. Place the nail and copper

strip in a copper sulphate solution made by dissolving one spoonful

of copper sulphate in a tumbler half full of water.

While the iron nail is being plated with copper, the copper strip is

being corroded. Since only the bare spaces are affected, the

copper will be eaten along the lines of the tracing. After

several hours, remove the copper strip, melt off the paraffin and

notice that the etching is quite clear. It will look as though the

design were directly engraved upon the copper.

EXPERIMENT 630 - How to etch on

steel

Steel or iron can be etched the same way as the copper in the

preceding experiment. Procure a piece of sheet steel or iron

and after coating it with paraffin trace the design upon it.

Then connect it to the positive wire leading to the carbon post and

attach a bright nail to the negative wire leading to the zinc post

of the battery.

Now place the steel and the iron nail an a solution of nickel

ammonium sulphate made by dissolving one spoonful of the compound in

a tumbler half full of water. Allow the current to pass

through the solution for several hours and then remove the steel and

melt off the paraffin. Notice that the design is etched upon

the steel.

194

GILBERT CHEMISTRY

EXPERIMENT 631 - Copper-plating by

immersion

Dissolve two measures of copper sulphate in a test tube half full of

water and place into this solution a small strip of clean

steel. Allow the steel to remain in the solution for half an

hour and notice after this time that it is coated with copper.

The reason for this is as follows: Some metals, like iron, are more

easily dissolved by acids than others, like copper. Therefore, when

iron is placed in a copper sulphate solution some of the iron goes

into solution to form iron sulphate and an equal amount of copper

goes out of solution as metallic copper and is deposited on the

iron.

EXPERIMENT 632 - Tin-plating by

contact

Dissolve six or eight measures of tartaric acid in a tin cup half

full of water. Now place into this solution a penny which has

been cleaned by boiling for several moments in a little vinegar.

Put the tin cup on the stove and allow the water to boil off.

Notice that after several minutes the penny will gradually become

coated with a bright silvery plating of tin.

EXPERIMENT 633 - Nickel-plating by

contact

Heat a test tube two-thirds full of water to boiling and dissolve in

it five measures of nickel ammonium sulphate.

Put a clean penny in a small tumbler and pour the nickel solution

upon it. Then place the strip of zinc included in the set in

the tumbler so that it comes in contact with the penny. Allow

the solution to stand for several minutes and notice after some time

that the penny is gradually coated with nickel.

EXPERIMENT 634 - Formation of a

current by contact of copper with zinc

Dissolve four measures of sodium bisulphate in a test tube full of

water and pour this solution into a tumbler. Drop into the

tumbler a clean penny and notice that the penny is unaffected by the

solution. Then place in the solution the strip of zinc so that

it touches the penny. Notice that bubbles of gas are formed on

the copper penny.

The zinc went into the solution to form zinc ions and left the zinc

plate negative. The hydrogen ions of the sodium hydrogen

sulphate were attracted to the copper penny, where they lost their

charges and became gaseous hydrogen and formed gas bubbles on the

penny. Therefore, an electrical current was set up in the

solution in which the strip of zinc became the negative electrode

and the copper penny the positive electrode.

EXPERIMENT 635 - Formation of a

current by contact of silver with zinc

Using the same solution and zinc strip as in the preceding

experiment, see if you can produce a current by means of a clean

silver coin. Notice that in this case bubbles of gas are also

formed on the silver coin, thereby setting up an electric current

between the zinc and silver. The explanation is the same as in

the preceding experiment.

ELECTROLYSIS

By electrolysis is meant the decomposition or breaking down of a

chemical compound to form new substances by the aid of the electric

current. Many important commercial industries depend upon this

process for making and isolating different substances. For

example, some metals like aluminum are prepared on a large scale by

passing an electric current through a molten bath of certain

aluminum compounds. Again, sodium hydroxide (caustic soda) and

chlorine gas, used to a large degree in

GILBERT

CHEMISTRY 195

making bleaching powder, are made by passing an electric current

through a solution of sodium chloride.

In the electrolysis of a solution of a chemical compound the

positive ion of the compound is always attracted to the negative

pole where it loses its charge and becomes an atomic

substance. In this state it reacts with the water present to

form a new compound and usually a gas, or is deposited on the

negative pole as a metal.

The negative ion, on the other hand, is attracted to the positive

pole where it loses its charge and becomes atomic in nature.

In this form it goes off as a gas or reacts with the water present

to form a new compound and a gas.

EXPERIEMENT 636 - The electrolysis

of sodium chloride

Dissolve one teaspoonful of common table salt (sodium chloride) in a

tumbler one-third full of water and add two or three drops of

phenolphthalein solution. Stir the solution a few times.

Now connect two or three dry cells in series and place the ends of

the negative and positive wires in this solution about one~half inch

apart. Do not let the wires touch. Notice that almost

immediately bubbles of gas are formed at each wire in the

solution. At the positive wire chlorine gas is formed, while

at the negative wire hydrogen is formed. Notice also that the

solution turns red, showing that a base of alkali is being

formed. What really happened may be expressed a little more

clearly as follows:

Negative wire

Positive wire |

Sodium

Chlorine gas |

water = sodium hydroxide |

hydrogen. |

EXPERIMENT 637 - The lemon electric

cell

Procure a fresh, juicy lemon and cut two small slits, one on each

side, as shown in the illustration.

Now clean the copper and zinc plates by scrubbing them. Insert

the zinc and copper strips in the lemon as shown in the

illustration. (Figure 46.) To prove the passage of an electric

current, touch your tongue to the ends of the zinc and copper

strips. Notice the slightly tingling sensation produced on the

tongue. This proves that a current is passing from one metal

to the other. When the external circuit is closed, the citric

acid (lemon juice) attacks the zinc, forming citrate of zinc.

By the separation of positive zinc from the zinc strip, the zinc

strip is made negative.

The positively charged hydrogen ions of the citric acid, which is in

the lemon, being displaced by the zinc, deliver their positive

charge to the copper. Thus the copper is positively, and the

zinc negatively, charged when the copper is joined to the zinc or

when the circuit is closed. The flow of electricity externally

is from the copper to the zinc.

The lemon cell polarizes quickly; so lift out the plates frequently

to remove the hydrogen bubbles.

EXPERIMENT 638 - How to clean

silverware electrolytically

If you have any silverware which is stained dark by exposure to the

air you can easily remove this stain, which is silver sulphide, by

treating the silverware as follows:

0btain an old aluminum pan and place the silver to be cleaned in the

pan. Now cover the silver with a solution of common salt or

baking soda made by dissolving two spoonfuls of the salt in each

quart of water used. Now place the pan on the stove and

196

GILBERT CHEMISTRY

allow the solution to boil for two minutes. Remove the

silverware and wash it with fresh water. Notice that the black

stains are removed and the silver is bright and clean.

The black stain or silver sulphide was reduced by the chemical

action taking place in the solution. A feeble electric current was

formed in which the aluminum pan acted as the negative pole and the

silverware as the positive pole. The electrolyte in this case was

the solution of common salt or baking soda.

The metal silver cleaners which you probably have seen advertised on

the market are simply metals of aluminum or zinc. The process

of cleaning silverware with these cleaners is the same as that used

in this experiment.

EXPERIMENT 639 - How to galvanize

iron with zinc

Mix together on a sheet of paper four measures of powdered zinc, one

measure of aluminum sulphate, one-half measure of powdered magnesium

and three measures of calcium carbonate.

Now take a wet cloth and after touching it to the mixture rub the

clean iron to be galvanized with some of the mixture. After

thoroughly rubbing, wash the iron free of the paste with water and

notice that it is coated with zinc.

Galvanized ironware is iron which has been treated with zinc

compounds in a similar manner.

EXPERIMENT 640 - How to galvanize

iron with nickel

Mix together on a piece of paper three measures of calcium

carbonate, one-half measure of powdered magnesium and five measures

of nickel ammonium sulphate.

Now rub thoroughly by means of a wet cloth some of this mixture on

the clean iron to be galvanized. Then wash off the paste with

a little water and notice that the iron is now plated with nickel.

[197]

LIST OF CHEMICALS WITH THEIR

FORMULA

| 1 -

Aluminum Sulphate |

Al2(SO4)3 |

.10 |

| 2 - Ammonium Chloride |

NH4Cl |

.10 |

| 3 - Ammonium Nitrate |

NH4NO3 |

.10 |

| 4 - Borax |

Na2B4O7.10H2O |

.10 |

| 5 - Boric Acid |

H3BO3 |

.10 |

| 6 - Litmus Paper |

|

.05 |

| 7 - Calcium Hypochlorite |

CaOCl2 |

.10 |

| 8 - Calcium Chloride |

CaCl2.6H20 |

.10 |

| 9 - Calcium Carbonate |

CaCO3 |

.10 |

| 10 - Camphor Gum |

C20H16O |

.10 |

| 11 - Calcium Oxide |

CaO |

.10 |

| 12 - Calcium Monophosphate |

Ca(H2PO4)2H2O |

.10 |

| 13 -Calcium Sulphate |

CaSO4.2H20 |

.10 |

| 14 - Calcium Sulphide

Paper |

|

.10 |

| 15 - Carbon Tetrachloride |

CCl4 |

.10 |

| 16 - Cobalt Chloride |

CoCl2.6H2O |

.10 |

| 17 - Cochineal |

|

.10 |

| 18 - Congo Red Paper |

|

.05 |

| 19 - Copper Strip |

Cu |

.05 |

| 20 - Copper Sulphate |

CuS04.5H2O |

.10 |

| 21 - Ferrous Ammonium Sulphute |

(NH4)2SO4.FeSO4.6H2O |

.10 |

| 22 - Ferric Ammonium Sulphate |

(NH4)2SO4.Fe2(SO4)2.24H2O |

.10 |

| 23 - Gum Arabic |

|

.10 |

| 24 - Glycerine |

CH2OHCHOHCH2OH |

.15 |

| 26 - Nickel-Steel Wire |

|

.10 |

| 27 - Insulated Copper Wire

|

|

.10 |

| 28 - Logwood |

|

.10 |

| 29 - Magnesium Sulphate |

MgSO4.7H2O |

.10 |

| 30 - Manganese Dioxide |

MnO2 |

.10 |

| 31 - Manganese Sulphate |

MnSO4.4H20 |

.10 |

| 32 - Nickel Ammonium

Sulphate |

(NH4)2SO4.NiSO4.6H2O |

.15 |

| 33 - Phenolphhalein |

(C6H4OH)2COC6H4CO |

.20 |

| 34 - Potassium Nitrate |

KNO3 |

.15 |

| 35 - Potassium

Permanganate |

KMnO4 |

.10 |

| 36 - Powdered Iron

Sulphide |

FeS |

.10 |

| 37 - Powdered Charcoal |

C |

.10 |

| 38 - powdered Iron |

Fe |

.10 |

| 39 - Powdered Magnesium |

Mg |

.15 |

| 40 - Powdered Zinc |

Zn |

.10 |

| 42 - Sodium

Bicarbonate |

NaHCO3 |

.10 |

| 43 - Sodium Bisulphate |

NaHSO4 |

.20 |

| 44 - Sodium Bisulphite |

NaHSO3 |

.15 |

| 45 - Sodium Carbonate |

Na2C03 |

.10 |

| 46 - Sodium Ferrocyanide |

Na4Fe(CN)6.12H2O |

.10 |

| 47 - Sodium Iodide

Solution |

NaI |

.10 |

| 48 - Sodium Silicate |

Na4SiO4 |

.10 |

| 49 - Sodium Sulphocyanate |

NaCNS |

.15 |

| 50 - Sodium Thiosulphate |

Na2S2O3.5H2O |

.10 |

| 51 - Strontium Nitrate |

Sr(N03)2 |

.10 |

| 52 - Sulphide Test Paper |

|

.10 |

| 53 - Sulphur |

S |

.10 |

| 54 - Tannic Acid |

C14H10O9 |

.20 |

| 55 - Tartaric Acid |

COOH(CHOH)2COOH |

.20 |

[198]

| 56 -

Turmeric Paper

|

|

.05 |

| 57 - Zinc Strip |

|

.15 |

| 59 - Nigrosine |

|

.10 |

| 61 - Red Saunders |

|

.05 |

| 63 - Gum Benzoin |

|

.15 |

| 64 - Collodion |

|

.10 |

| 65 - Acetic Acid |

CH3COOH |

.10 |

| 68 - Denatured Alcohol

|

C2H5OH |

.05 |

| 69 - Ammonia |

NH4OH |

.05 |

| 73 - Strontium Chloride |

SrCl2.6H2O |

.10 |

| 74 - Acetone |

(CH3)2CO |

.10 |

| 75 - Chrome Alum |

Cr2(S04)3.K2S04.24H2O

|

.10 |

Minerals

| X1500-A |

Galena |

.10 |

| X1500-B |

Stibnite |

.10 |

| X1500-C |

Chalcopyrite |

.15 |

| X1500-D |

Pyrite |

.10 |

| X1500-E |

Magnetite |

.10 |

| X1500-F |

Pyrolusite |

.10 |

| X1500-G |

Sphalerite |

.10 |

| X1500-H |

Malachite |

.10 |

| X1500-I |

Calcite |

.10 |

| X1500-J |

Fluorite |

.05 |

| X1500-K |

Halite |

.10 |

| X1500-L |

Orthoclase |

.05 |

| X1500-M |

Talc |

.10 |

| X1500-N |

Apatite |

.10 |

| X1500-O |

Muscovite |

.10 |

| X1500-P |

Garnet |

.05 |

| X1500-Q |

Quartz |

.10 |

APPARATUS

AND EQUIPMENT

| X861-B |

Wand |

.05 |

| X1547 |

Thermometer |

.15 |

| X1551 |

Test Tube

Rack - Large |

.25 |

| X1555-A |

Scale - Complete |

.50 |

| X1557 |

Test Tube Rack - Medium |

.20 |

| X1570 |

Test Tube Rack - Small |

.15 |

| *X1584 |

Gas Generating Bottle - Glass |

.10 |

| X1584-A |

Alcohol Lamp |

.20 |

| X2085 |

Metal Alcohol Lamp |

.15 |

| X3327 |

Tank |

.30 |

| P-57-A |

Rod |

.02 |

| P859 |

Ring for Ink Trick |

.05 |

| P860 |

Black Cloth for Ink Trick |

.05 |

| P1502 |

4" Test Tubes |

.05 |

| P1503 |

Glass Rod |

.05 |

| *P1504 |

Glass Tubes 4 1/2 |

.05 |

| P1518 |

Spoon |

.05 |

| P1522 |

Filter Paper Disc |

6 for .05 |

| P1556 |

Test Tube Brush |

.10 |

| P1548 |

Flask |

.50 |

[199]

| P1544

|

Self Generating Torch with Swab

and Cleaning Wire |

.75 |

| P1549 |

Beaker |

.50 |

| *P1560 |

Right Angle Tube-Long |

.05 |

| P1563 |

Test Tube Holder |

.10 |

| P1574 |

Charcoal Block |

.20 |

| P1577 |

Short Right Angle Tube |

.05 |

| *P1578 |

Glass Funnel |

.15 |

| P1580 |

Small Shovel |

.02 |

| P1582 |

Metal Test Tube Rack |

.10 |

| P1583 |

Carbon Electrodes |

.10 |

| P1589 |

Porcelain Pestle |

.15 |

| P1593 |

Glass Mortar |

.10 |

| P1598-A |

Cork with Hole |

2 for .05 |

| P1599 |

Candle |

.03 |

| *P3308 |

Rubber Coupling |

.01 |

| P3309-A |

Rubber Tubing 2 ft |

.35 |

| *P3310 |

No. 2 Rubber Stopper - 2 holes |

.05 |

| P3311 |

No. 1 Solid Rubber Stopper |

.10 |

| P3312 |

No. 1 One Hole Rubber Stopper |

.05 |

| P3313 |

No. 0 Two Hole Rubber Stopper |

.10 |

| P3314 |

No. 0 One Hole Rubber

Stopper |

.05 |

| P3328 |

Cork-No. 5 Standard Taper |

.05 |

| P4727 |

Horseshoe Magnet |

.10 |

| P5607 |

Glass Blowers Pipe |

.25 |

| P8704 |

Quill Brush |

.03 |

| M1706 |

Small Chemical ManuaL |

.25 |

| M1710 |

Large Chemical Manual |

.35 |

| M1735 |

Medium Chemical ManuaL |

.35 |

|

Chemical Magic Manual |

.25 |

|

Mineralogy Manual |

.25 |

|

Glass Blowing Manual |

.25 |

The parts marked * are necessary to make the Gas Generating

Apparatus. Kindly enclose check, money-order or stamps with your

order.

THE A. C. GILBERT COMPANY

New Haven, Conn.

[Back

Cover]

"The Science Notebook"

Copyright 2008-2018 - Norman Young

The

Science Notebook

The

Science Notebook The

Science Notebook

The

Science Notebook