TITLE

2

INTRODUCTION

NOWADAYS there are so many

very interesting things going on all about us that very often

we are likely to overlook things which have an important

bearing on our everyday life. Small things which we are so

used to having around that we never stop to think what they

really mean to us.

For instance water. It's nice to drink, and bathe in

but very few of us ever stop to consider the innumerable uses

water is put to and what a great influence it has on many

things we do. Most of us are satisfied to turn on the faucet

and get our water in that way. If something is wrong and the

water doesn't come from the faucet we call up the plumber, but

we do not realize what has gone wrong simply because we do not

understand how a house is piped for water nor do we understand

why water gets into the pipes, etc.

Then air - another thing which we couldn't live

without and yet few appreciate its value. Air and water give

us tremendous results as pneumatic and hydraulic pressure. A

knowledge of these great forces which most boys are so

familiar with and still do not understand thoroughly will put

you up far ahead of your boy friends. Most boys take things

too much for granted; it is the clever boy Who digs into

things and find out the reasons.

It is the earnest hope of the authors of this book

that the boys who read it will have a better understanding of

water and air, how they are used, and what they mean to us.

Sincerely yours,

COPYRIGHTED, 1920, BY A. C. GlLBERT

NEW HAVEN, CONN.

HYDRAULIC AND PNEUMATIC ENGINEERING

3

INDEX TO ILLUSTRATIONS

HYDRAULIC APPLIANCES

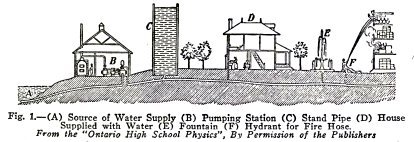

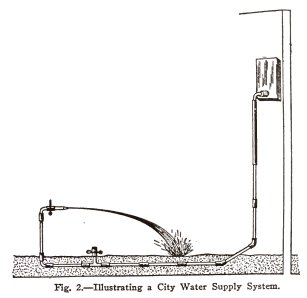

City Water Supply Figs. 1, 2 Pages 5, 6

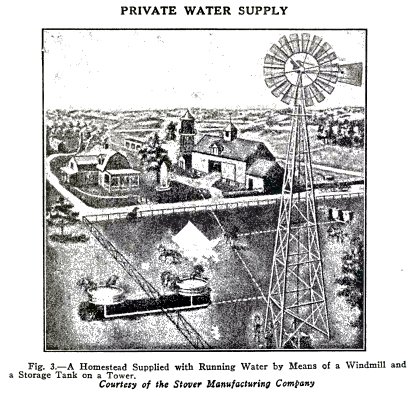

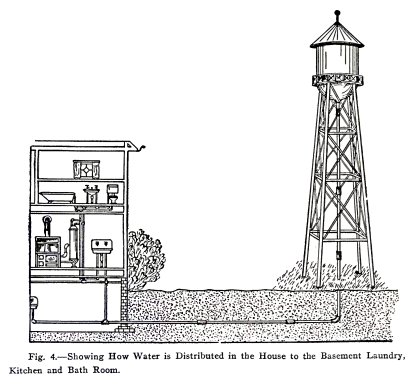

Private Water Supply Figs. 3, 4 Pages 7, 8

Attic Tank System Figs. 7, 8 Page 10

Water Supply From Spring Figs. 11, 12 Page 12

Pneumatic Tank Figs. 22, 23 Page 16

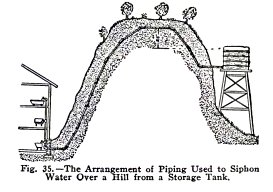

Siphon Over Hill Figs. 31, 33, 35 Pages 21, 22

Lift Pump Figs. 62, 63 Page 43

Force Pump Fig. 65 Page 45

Hydraulic Press Figs. 68A, 73 Pages 48, 52

Hydraulic Elevator Figs. 68B, 75 Pages 48, 53

Hydraulic Lift Lock Figs. 68C, 79, 81, 82 Pages 48,

55, 58

Depth Bomb Fig. 90 Page 66

Torpedo Figs. 91, 92 Page 67

Submarine Fig. 93 Page 68

Battleship Fig. 98 Page 72

Raising Sunken Ships Figs. 105, 106, 108 Pages 79, 80,

81

Floating Dry Docks Figs. 109, 110 Pages 82, 83

Air Lock in Pipes Figs. 120, 121 Pages 90, 91

PNEUMATIC APPLIANCES

Magdeburg Hemispheres Fig. 122 Page 93

Barometer Figs. 129, 130 Page 99

Air Zones Fig. 131 Page 100

Altitude Gauge Fig. 132 Page 101

Air Lift Pump Figs. 139, 140 Pages 105, 106

Balloons Figs. 144, 145 Pages 110, 111

Helium Balloons Fig. 146 Page 112

Air Brakes Figs. 156, 157 Pages 121, 122

Flame Thrower Fig. 158 Page 123

Fire Extinguisher Fig. 160 Page 124

Bicycle Pumps Fig. 165 Page 128

Air Compressor Fig. 167 Page 130

Sand Blast Fig. 168 Page 130

Pneumatic Paint Brush Fig. 170 Page 132

Diving Bell Figs. 172, 173 Pages 133, 134

Pneumatic Caisson Figs. 176, 177 Page 137

Torpedo Discharge Tube Fig. 178 Page 138

Air From Sea Water Fig. 180 Page 140

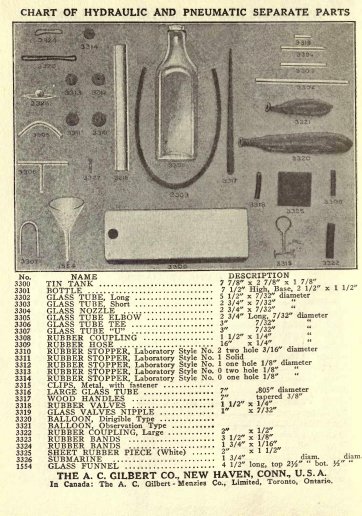

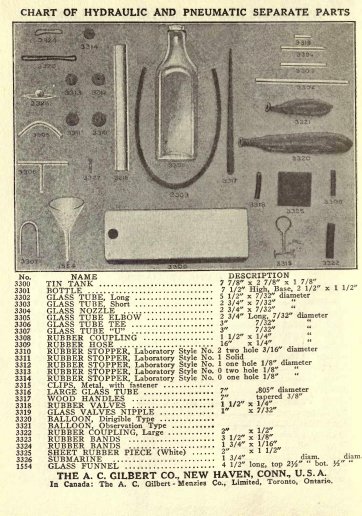

CHART OF

HYDRAULIC AND PNEUMATIC SEPARATE PARTS

Hydraulic and Pneumatic

Engineering

Hydraulic Engineering is the Engineering which deals

with water and other liquids.

Pneumatic Engineering is the Engineering which deals

with air and other gases.

WATER SUPPLY

Boys, have you running water in your homes? If so, do

you know how it gets there? You will show how with

this Engineering set.

If you live in a city, your running water is supplied

in one of three ways: first, it is pumped

into a standpipe or reservoir; second, it is

brought from a distant lake or stream at a higher level; or

third, it is pumped directly into the city mains.

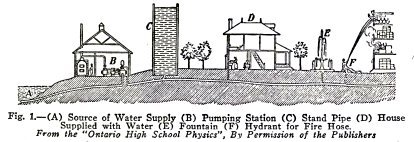

The standpipe method is illustrated in Fig. 1. The

water is pumped by means of a force pump B from a river or

lake A into a standpipe C, from which it runs by gravity

through the under-ground pipes or mains to the houses D,

fountains E and hydrants F. This system is used in towns and

small cities situated in a flat region, because it is the

cheapest means of getting the water above the level of the

highest house faucet in the town.

If the town is situated near a hill, the usual

practice is to build a large cement lined reservoir on the

hill and to pump the water into this instead of into a

standpipe. In either case the water runs by gravity through

the mains and submains to the houses, hydrants, etc.

If the city is very large, the usual practice is to

bring the water from a lake or stream at a higher level. New

York is supplied with water in this way.

See page 145 for diagram of apparatus needed to

perform experiments in this book.

6 HYDRAULIC AND

PNEUMATIC ENGINEERING

If the city is very large and if an elevated lake or

stream cannot be found within a reasonable distance, the usual

practice is to pump the water directly into the city mains,

from the nearest river or lake.

In all cases the greatest care is taken to see that

the water is pure. The land bordering the elevated lake or

stream is kept free from all sources of contamination and in

addition the water is filtered. If the water is pumped from a

lake, the intake pipe is run out into the lake for a long

distance, to get the purest water and in addition the water is

filtered. If the water is pumped from a river near the city,

it is taken in above the city and is filtered.

EXPERIMENT No. 1

To make and operate a city

water supply system in which the water comes from a standpipe,

reservoir or lake.

Arrange the apparatus as shown in Fig. 2 and bury the mains an

inch or two in sand or earth if convenient. Allow the water to

run from the house faucet, that is, the nozzle. Attach an

elbow, hose, and nozzle to the hydrant, that is, the coupling,

and allow the water to run.

You have here shown how the water runs from a

standpipe, reservoir, or elevated lake, through the mains to

the hydrants in the streets of a city and to the faucets in

the houses.

NOTE 1. When

you wish to insert a glass tube into a rubber stopper or

coupling always place the stopper or coupling in a glass of

water to wet the rubber on the inside, then insert the glass

tubes with a twisting motion. Always hold the glass tube near

the end you are inserting into the rubber stopper or coupling.

Thi is very important, because, if you hold the tube too far

back, you may break it.

HYDRAULIC AND PNEUMATIC

ENGINEERING 7

NOTE 2. When

you are through with an experiment always take the apparatus

apart. Be sure particularly not to leave a glass tube in a

rubber coupling or stopper because the tube will stretch the

rubber permanently and the glass and rubber will stick

together.

NOTE 3. Make

the experiments out of doors, in the garage, in the basement,

or in the bathroom. Keep all unused tubes in the box where you

will not step on them.

NOTE 4. Let

Dad enjoy this with you; he was a boy once, and will enjoy the

fun as much as you do.

If you live in the country, or in a town where there

is no public water supply system, and if you have running

water in your home, you must have a private water supply

system of some kind.

8 HYDRAULIC AND PNEUMATIC

ENGINEERING

In the system shown in Fig. 3 the water is pumped by

means of a windmill and force pump into a tank on a tower and

from this it runs by gravity to the house, the fountain, and

the stable. The drawing in Fig. 4 shows how the water from the

tank is distributed to the laundry, kitchen, and bathroom of

the house.

EXPERIMENT No. 2

To

make and operate a private water supply system in which the

water is stored in a tank on a tower.

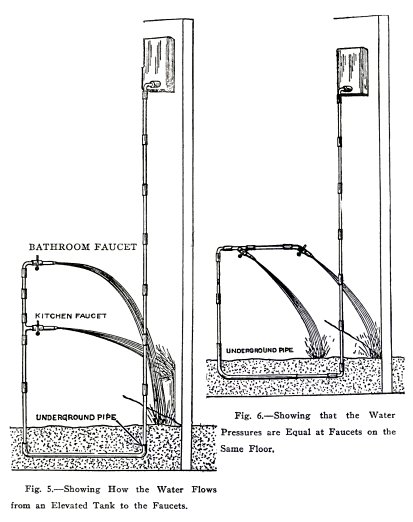

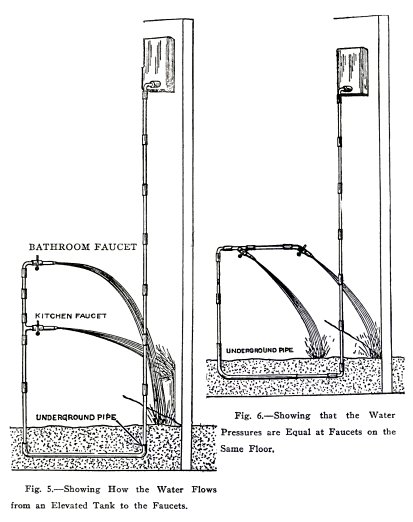

Arrange the apparatus as in Fig. 5. Hold the nozzles

horizontal and open them one at a time, then together. Is the

stream from the lower nozzle longer than that from the upper?

Arrange the apparatus as shown in Fig. 6. Open the

nozzles when horizontal and at the same level Are the streams

of equal lengths?

HYDRAULIC AND PNEUMATIC

ENGINEERING 9

You have shown here how the water runs from a tank on

a tower through the vertical pipe and underground pipe to the

faucets in the house. You have shown also that the pressure is

greater at a lower faucet than at an upper faucet and that the

pressures are equal at faucets on the same level.

10 HYDRAULIC AND

PNEUMATIC ENGINEERING

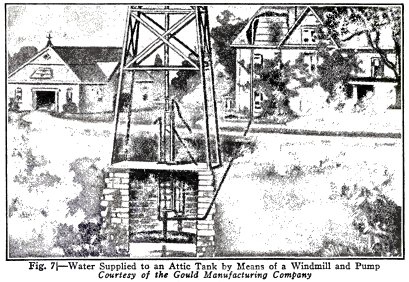

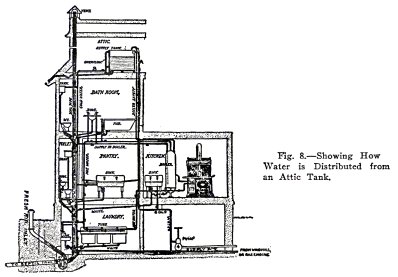

In Fig. 7 the water is pumped by a wind-mill and force

pump into a tank in the attic of the house, and from there it

runs by gravity to the various house fixtures as shown in Fig.

8. The force pump is often driven by a gas engine instead of

by a windmill. The hand pump (4) Fig. 8 is used only when the

gas engine or windmill is out of order.

HYDRAULIC AND PNEUMATIC

ENGINEERING 11

EXPERIMENT No. 3

To

make and operate a private water supply system in which the

water is stored in an attic tank.

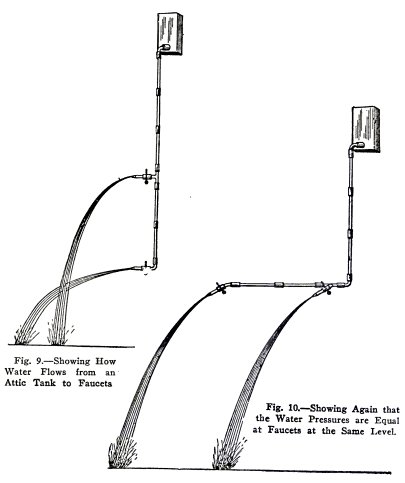

Arrange the apparatus as in Fig. 9. Hold the nozzles

horizontal one above the other and open them together. Is the

longer stream from the lower nozzle? That is, is the greater

pressure at the lower faucet?

Arrange the apparatus as in Fig. 10. Hold the nozzles

horizontal and open them together. Are the streams of the same

length? That is, are the pressures equal?

You have shown here again that the greater pressure is

at the lower faucet and that the pressures are equal at

faucets on the same level.

12 HYDRAULIC AND PNEUMATIC

ENGINEERING

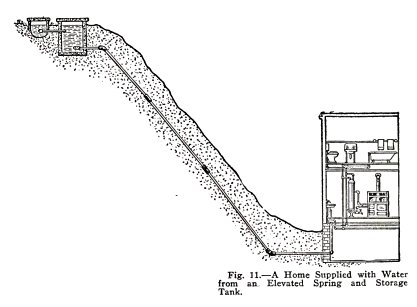

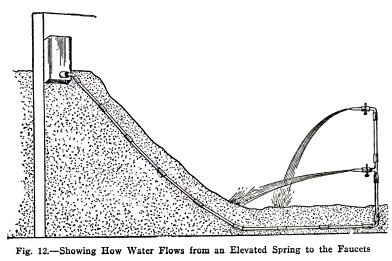

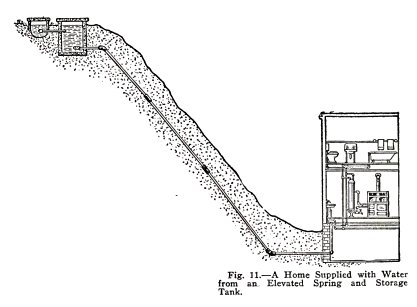

In Fig. 11 the water from an elevated spring runs by

gravity into a storage tank and then through an underground

pipe to the house fixtures.

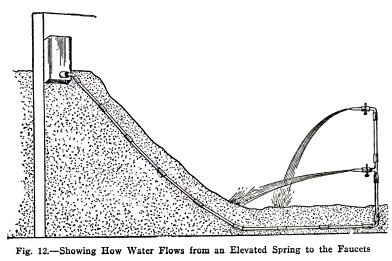

EXPERIMENT No. 4

To

show how water is brought from an elevated lake or

spring.

Arrange the apparatus as shown in Fig. 12. Place the

tank on a mound of sand or earth and bury the underground pipe

to a depth of one or two inches. Allow the water to run.

You have shown here how the water is brought to a city

from an elevated lake or stream, or how it is brought to a

private house from an elevated spring.

HYDRAULIC AND PNEUMATIC

ENGINEERING 13

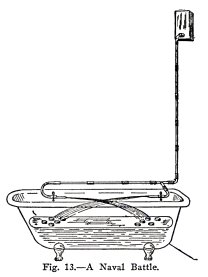

A NAVAL BATTLE

GAME No. 1

You can invent all sorts of games to be played with

this Engineering set. The Naval Battle is one and it is an

excellent game for a hot day.

Float a number of tin cans, tumblers, or cups on water in a

bath tub, or in a wash tub, Fig. 13. Arrange the apparatus as

shown. Each player directs his stream against the warships of

the other, and the winner is the one who first sinks all the

enemy war ships.

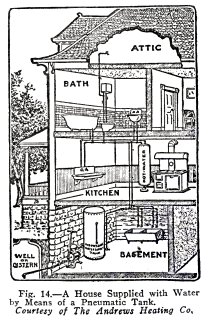

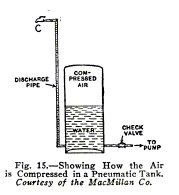

PNEUMATIC TANK SYSTEM OF WATER SUPPLY

The pneumatic tank system of water supply is

illustrated in Fig. 14. The water is pumped into the

bottom of an air-tight steel tank and compresses the air

in the tank to smaller volume at the top. This compressed

air then forces the water out through the discharge

pipe at the bottom of the tank and lifts it to the faucets

in the rooms above. The interior of the tank is

represented in Fig. 15. The compressed air at the top of

the tank forces water up the discharge pipe when any

faucet C is opened.

14 HYDRAULIC AND PNEUMATIC

ENGINEERING

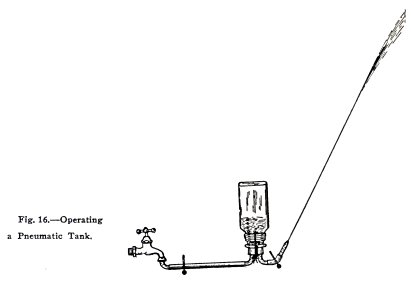

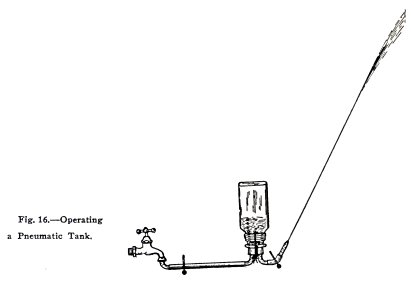

EXPERIMENT No. 5

To make and operate a pneumatic

tank.

Arrange the apparatus as shown in Fig. 16. It is

necessary to fasten the stopper in the bottle very securely.

Do this as follows: Insert two elbows into the two-hole rubber

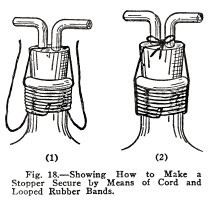

stopper and twist the stopper firmly into the neck of the

bottle. Next loop three strong rubber bands together as shown

in Fig. 17, pass a stout cord over the stopper and wind the

stretched rubber bands around the neck and cord. Now slip the

last end of the bands under the last winding to hold it, (1)

Fig. 18, then tie the ends of the cord up over the stopper,

(2) Fig. 18, and you will find that the stopper is very

secure.

The stretched rubber bands make a very secure tie

because each Stretched winding grips the cord. You will use

this tie often in your experiments.

Note - You

can use the tee and one-hole stopper instead of the elbows and

two-hole stopper if you prefer.

HYDRAULIC AND PNEUMATIC

ENGINEERING 15

Now: open the clip on the hose, open the faucet Fig.

16, slightly, run water into the bottle until it is half full,

close the faucet, close the clip on the hose, remove stopper

from faucet, point the nozzle upward, and open the clip on the

nozzle.

Does the compressed air force the water out with

surprising force? If you have no water faucet handy,

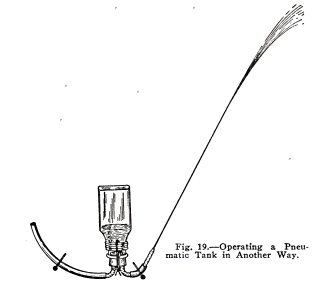

illustrate the pneumatic tank as shown in Fig. 19. Fill the

bottle half full of water, tie the stopper in place, force air

in with your mouth or with a bicycle pump, and observe the

stream as before.

Find a larger bottle, which your stoppers will fit,

and repeat these experiments.

You have shown here how the compressed air in a

pneumatic tank forces the water out through the discharge

pipe. Repeat and make experiments of your own.

Note - Do not

attempt to fill the bottle more than half full of water

because the air pressure increases rapidly as the air is

compressed and it blows out the nozzle or separates the rubber

tubes from the elbows.

16 HYDRAULIC AND PNEUMATIC

ENGINEERING

RAPID FIRE WATER GUN

GAME No. 2

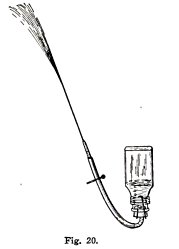

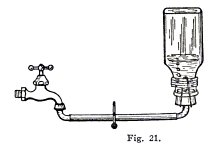

Arrange the bottle as shown in Fig. 21 and fill it

half full of water. Replace the elbow by a nozzle as in Fig.

20 and your rapid fire water gun is complete. Open the clip

for an instant only for each shot.

Arrange a battle with one or more on a side, each

soldier armed with a rapid fire water gun. A man is wounded

when hit on the arm or leg and must afterwards fight without

the arm or leg; a man is killed when hit on the body or head.

The side loses which first has all of its men killed. Use

forts, trenches, tanks, etc.

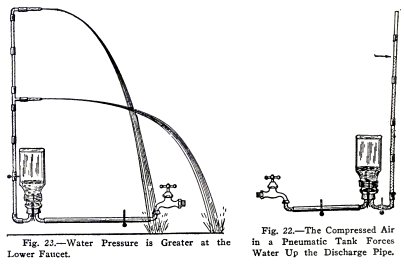

EXPERIMENT No. 6

To

make and operate a pneumatic tank system of water supply.

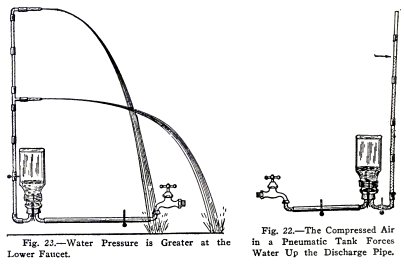

Arrange the apparatus as in Fig. 22, fill the bottle

half full of water as above, open the clip on the discharge

tube, and observe the height to which the compressed air lifts

the water.

Repeat with the apparatus as in Fig. 23. Do you

observe that the stream from the lower nozzle is longer than

that from the upper; that is, that in the pneumatic system

also the pressure is always greater at the lower faucet?

HYDRAULIC AND PNEUMATIC

ENGINEERING 17

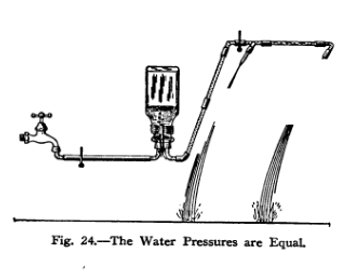

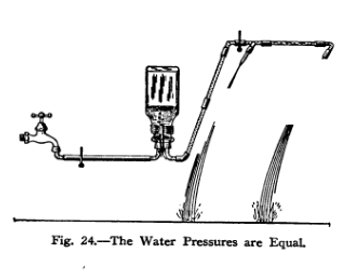

Repeat with the apparatus as

in Fig. 24. Do you observe that the streams are of the same

lengths, that is, that the pressures are equal at

faucets on the same level?

You have shown here how the compressed air in a

pneumatic tank forces water up to the faucets above; also that

the greater pressure is at the lower faucet, and that the

pressures are equal at faucets on the same level.

18 HYDRAULIC AND PNEUMATIC

ENGINEERING

WATER AND AIR

WATER AND AIR

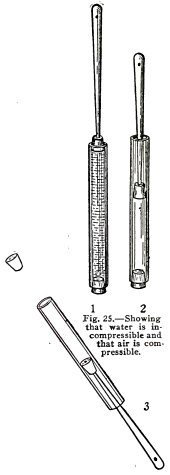

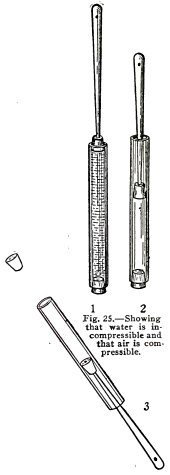

EXPERIMENT No. 7

To

show that water is incompressible and that air is

compressible.

Arrange the apparatus as in Fig. 25, fill the tube

with water and try to compress it. You cannot do so because

water is nearly incompressible.

Note: Water

as slightly compressed by very great pressures; for example,

if your tube were 10 in. long and you could apply a pressure

of 3000 lbs. per square inch, the water would be compressed

1/10 inch.

Now empty out the water and try to compress the air in

the tube as in (2) Fig. 25. You will find that you can do so

quite easily because air is quite compressible.

You have demonstrated here that water is

incompressible (nearly) and that air is compressible. You know

from this that in the pneumatic tank it is the air which is

compressed and not the water.

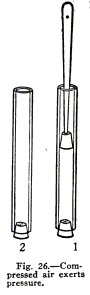

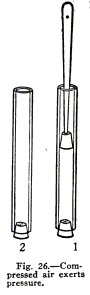

EXPERIMENT No. 8

To

show that compressed air exerts pressure.

Use the apparatus shown in Fig. 26. Wet the inside of

the tube, wet the plunger and rub it on a cake of soap to make

it slippery, shove the plunger into the tube (1) and let it go

suddenly.

Do you find that the compressed air drives the plunger

out violently (2)?

Repeat with a little water above the plunger to serve

as a lubricant.

Note: When you

shove the handle into the stopper you expand the stopper

slightly. You should expand it until it fits the tube snugly

but not too tightly.

Hold the apparatus as in (3), Fig. 26 and force the

handle in until the compressed air drives out the end stopper.

You have shown here that compressed air exerts

pressure and you will understand from this how the compressed

air drives the water out of a pneumatic tank;

HYDRAULIC AND PNEUMATIC

ENGINEERING 19

also you will understand why the tank must be made of

steel, namely, to stand the pressure of the compressed air.

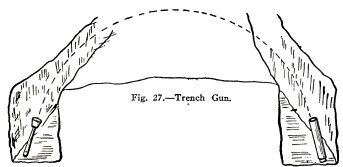

TRENCH GUN

GAME No. 3

You can imitate the Stokes trench gun as follows. Put

two long strips of paper on the ground three feet apart to

represent the enemy trench. Now go back 20 or 30 feet or more,

point the tube upward and toward the enemy trench, force the

plunger in and release it suddenly. The game is to try to drop

the bomb, that is, the plunger, into the enemy trench. The

winner is the one who does it most often in a given number of

trials.

Note: Keep the

inside of the tube wet, the plunger wet and slippery with

soap, and a little water above the plunger.

HEIGHT AND DISTANCE CONTEST

GAME No. 4

Use the apparatus as above. The game is to see who can

shoot the plunger to the greatest height and to the greatest

distance.

POP GUN

GAME NO. 5

Use the apparatus as a pop gun, Fig. 28. The games

are: first, to try to hit a bull's eye, with the end stopper;

second, to see which can shoot it to the greatest distance and

the greatest height.

20 HYDRAULIC AND PNEUMATIC

ENGINEERING

THE SIPHON

The siphon is used in many water supply systems to

make water flow over the top of a storage tank or over a hill

from a spring on one side to a house on the other, and so on.

You will first show how the siphon works, then you

will show how it is used in water supply system, and later you

will show why it works as it does.

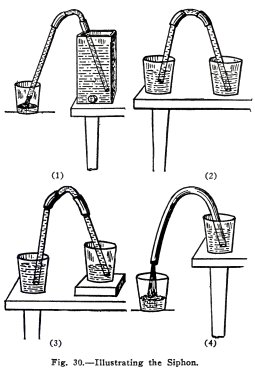

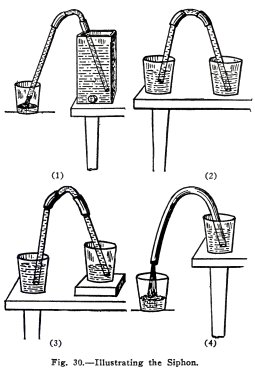

EXPERIMENT No. 9

To make and operate a siphon.

Arrange the apparatus as in (1), Fig. 30. Place one

arm of the siphon in the water and while holding the other arm

outside the tank below the water level suck the air out of the

siphon until the water runs.

Does the water run up hill to the top of the siphon

and then down hill into the tumbler?

Siphon water out of a full tumbler into an empty

tumbler and while the water is running stand them side by side

on the table, (2), Fig. 30.

Does the water stop when the level is the same in both

tumblers?

HYDRAULIC AND PNEUMATIC

ENGINEERING 21

Place one tumbler on a block of wood or a book as in

(3), Fig. 30.

Does the water flow from the upper tumbler to the

lower, and does the flow again stop when the levels are the

same?

Place the block under the other tumbler.

Are the results the same?

Repeat the above experiments with the rubber hose,

(4), Fig. 30, used as a siphon.

You have shown here: that the water runs uphill in one

arm of a siphon and downhill in the other; that it always runs

from the higher

water level to the lower; and that it stops running

when the water levels are the same.

You will show "why" the water runs, in later

experiments.

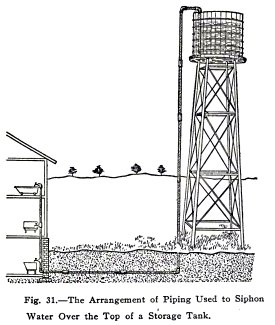

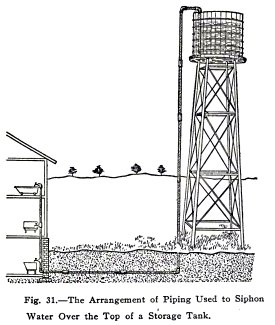

HOW THE SIPHON IS USED IN WATER SUPPLY SYSTEMS

EXPERIMENT No. 10

To show how the siphon is used in water supply systems.

It is rather difficult to make a water-tight

connection in the bottom of a water tank and in many cases it

is not done, but instead the water is siphoned out over the

top, as shown in Fig. 31.

Illustrate this as shown in Fig, 32.

22 HYDRAULIC AND PNEUMATIC

ENGINEERING

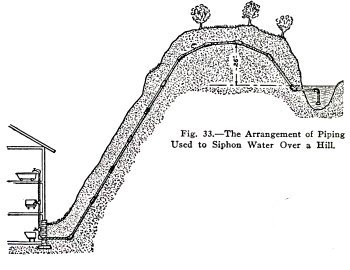

In some cases it happens that there is a good spring of water

on one side of a hill and the home in which the water is

wanted is on the other side. If the highest point of the

siphon is not more than about 25 feet (34 feet is the

theoretical limit) above the water surface in the spring, and

if the house faucets are below the level of the water in the

spring, the water can be siphoned over the hill as shown in

Fig. 33.

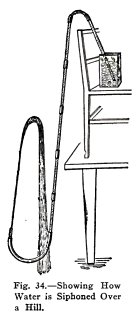

Illustrate this as shown in Fig. 34, where the back of

the chair represents the hill.

HYDRAULIC

AND PNEUMATIC ENGINEERING 23

Water can be siphoned from a storage tank or reservoir

over a hill as well as from a spring and the siphon can start

at the bottom of the reservoir if this is more convenient, see

Fig. 35.

Illustrate this as shown in Fig. 36.

You have here illustrated three ways in which the

siphon is used in water supply systems. You will show later

why a siphon cannot lift water over a rise of more than about

25 feet and why the greatest theoretical lift is 34 feet.

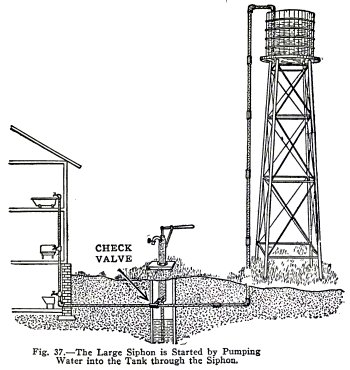

HOW TO START

A LARGE SIPHON

EXPERIMENT No. 11

To illustrate

different ways of siphon.

You could not start a large siphon by sucking the air

out of it with your mouth. How then are you going to start it?

You will illustrate three ways. The object in all cases is to

get the air out of the siphon and this is usually done by

filling it with water.

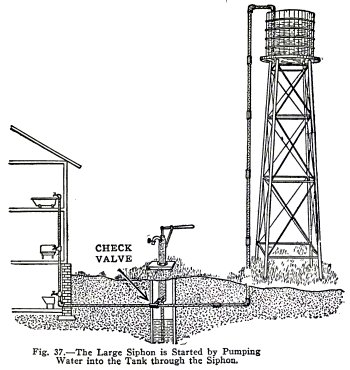

In the case illustrated in Fig. 37, the faucets are

all closed and the air is driven out of the siphon by pumping

water into the tank through the siphon. The check valve

prevents the water from running back into the pump, and when

the faucets are opened the water runs.

24 HYDRAULIC AND PNEUMATIC

ENGINEERING

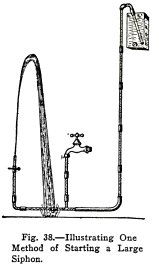

This experiment is illustrated by means of the apparatus shown

in Fig. 38. The faucet here represents the pump. Start with

the tube empty except for the air in it, close the clip under

the nozzle, open the faucet until the tank is full of water,

close the faucet, and open the clip.

Does the water run through the siphon to the nozzle?

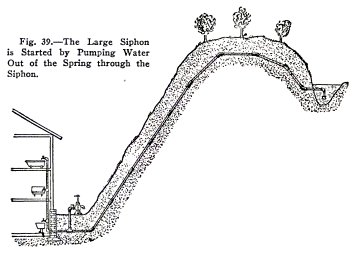

When the water is siphoned over a hill from a spring,

the siphon is usually started by connecting it to the suction

side of a pump placed on the other side of the hill in or near

the house, as shown in Fig. 39.

To start the siphon, the

house faucets are closed, the stop cock at the pump is

opened and the pump is operated until the water comes

freely; then the stop cock is closed and the water runs

whenever a faucet in the house is opened.

HYDRAULIC AND PNEUMATIC

ENGINEERING 25

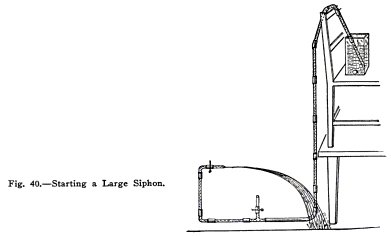

This is illustrated by

arranging the apparatus as shown in Fig. 40; the tee branch

represents the pump connection and the end branch represents

the house pipe.

Close the house pipe, apply

your lips to the tee branch (to represent the working of the

pump) and suck air out of the siphon until the water flows,

then close the tee branch and open the house pipe. Does the

water flow?

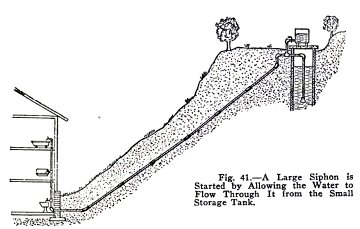

In many cases the water is

siphoned over the top of a hillside well to a house at a lower

level and the siphon is started by means of a pump near the

house as illustrated in the last experiment. Generally,

however, a small storage tank of water at the top of the

siphon is used to start it, see Fig. 41. The small storage

tank is filled by means of a pump (not shown), or by means of

a pail used to dip water from the well.

The

Science Notebook

The

Science Notebook The

Science Notebook

The

Science Notebook