The

Science Notebook

The

Science NotebookHenley's Book of Formulas, Recipes and Processes

Home Terms of Use Safety Contact Us Experiment Pages Downloads Supplies Useful Links!

Henley's Twentieth Century Book of Formulas, Recipes and Processes - Pages 301-325

[301]

ENAMELING

With good coal and a furnace constructed to utilize the heat given off to the fullest extent, there may still be unnecessary waste. The arrangement of the bars should only be made by those who fully understand the character of the coal and the objects in view. The fireman in charge should be thoroughly experienced and reliable, as much waste is frequently traced to imperfect feeding of the fuel.

Each charge of articles should be as large as possible, as fusing will take place equally as well on many articles as on few. The charges should follow one another as rapidly as can be conveniently carried out; and where this is not done there is a lack of organization which should be immediately remedied.

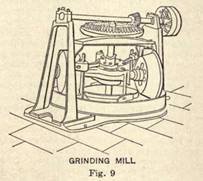

Mills. Any hard substances must first be broken up and pounded in a pounding or stamping mill, or in any other suitable manner, thus reducing the lumps to a granular condition. When this has been done, the coarse is separated from the fine parts and the former again operated on. The next process is roller grinding for reducing the hard fritted granular particles to a fine powder. These mills vary in construction, but a satisfactory type is shown in Fig. 9. Motion is con-

veyed by a belt to the driving pulley, and this is transmitted from the pinion to the large bevel, which is connected by a shaft to the ground plate. As this revolves the material causes the mill wheels to revolve, and in this way the material is reduced to a powder. The rollers are of reduced diameter on the inner side to prevent slippage, and when all the parts are made of iron, the metal must be close grained and of very hard structure, so as to reduce the amount removed by wear to a minimum. When the materials are ground wet, the powder should be carefully protected from dust and thoroughly dried before passing to the next operation.

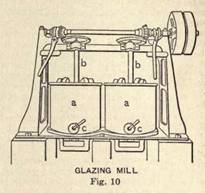

The glazing or enamel mills are shown in Fig. 10. These mills consist of a

strong iron frame securely bolted to a stone foundation. In the sketch shown the framing carries 2 mills, but 3 or 4 can be arranged for. A common arrangement for small factories consists of 2 large mills, and 1 smaller mill, driven from the same shaft. One of the mills is used for foundation or gray mixings, the second for white, and the smallest one for colored mixings. In these mills it is essential that the construction is such as to prevent any iron fitting coming into contact with the mixing, for, as has already been explained, the iron will cause discoloration. The ground plate is composed of quartz and is immovable. It is surrounded by a wooden casing as shown at a and bound together by iron hoops. The millstones are heavy, rectangular blocks of quartz, called "French burr stone," and into the center the spindle, b, is led. The powdered material mixed with about three times its bulk of water is poured into the vats, a, and the grinding stones are then set in motion. When a condition ready for enameling has been reached the mixture is run off through the valves, c. Each mill can be thrown out of gear when required, by means of a clutch box, without interfering with the working of the others. The grinding stones wear rapidly and require to be refaced from time to time. To avoid stoppage of the work, therefore, it is advisable to always have a spare set in readiness to replace those removed for refacing. The composition of the stones should not be neglected, for, in many cases, faults in the enamel have been traced to the wearing away of stones containing earthy or metallic matter.

[302]

ENAMELING

Enamel Mixing. All constituents of which an enamel glaze is composed must be intimately mixed together. This can only be done by reducing each to a fine powder and thoroughly stirring them up together. This part of the work is often carried out in a very superficial manner, one material showing much larger lumps than another. Under circumstances such as these it is absurd to imagine that in fusion equal distribution will take place. What really happens is that some parts of the mass are insufficiently supplied with certain properties while others have too much. A mixture of this class can produce only unsatisfactory results in every respect, for the variations referred to will produce variations in the completeness of fusion in the viscous character of the mass, and in the color.

The mixing can be done by thoroughly stirring the various ingredients together, and a much better and cheaper system is mixing in rotating barrels or churns. These are mounted on axles which rest in bearings, one axle being long enough to carry a pulley. From the driving shaft a belt is led to the cask, which then rotates at a speed of from 40 to 60 revolutions per minute, and in about a quarter of an hour the operation is complete. The cask should not exceed the 5-gallon size, and should at no time be more than two-thirds full. Two casks of this kind give better results than one twice the size. The materials are shot into the cask in their correct proportions through a large bung hole, which is then closed over by a close-fitting lid.

Mixings. For gray or fundamental coatings:

I.

Almost any kind of glass 49 per cent

Oxide of lead 47 per cent

Fused borax 4 per cent

II.

Glass (any kind) 61 percent

Red lead 22 per cent

Borax 16 per cent

Niter 1 per cent

III.

Quartz 67.5 per cent

Borax 29.5 per cent

Soda (enameling) 3 per cent

The above is specially adapted for iron pipes.

IV.

Frit of silica powder 60 per cent

Borax 33 per cent

White lead 7 percent

Fused and then ground with-

Three-tenths weight of silica frit.

Clay, three-tenths weight of silica frit.

Magnesia, one-sixth weight of white lead.

V.

Silica 65 per cent

Borax 14 per cent

Oxide of lead 4 percent

Clay 15 per cent

Magnesia 2 per cent

No. V gives a fair average of several mixings which are in use, but it can be varied slightly to suit different conditions of work.

Defects in the Gray or Ground Coating. Chipping is the most disastrous.

This may be prevented by the addition of some bitter salt, say from 3 to 4 per cent of the weight of the frit.

The addition of magnesia when it has been omitted from the frit may also act as a preventive, but it should only be added in very small quantities, not exceeding 2.5 per cent, otherwise the temperature required for fusion will be very great.

Coating and Fusion. Difficulties of either may generally be done away with by reducing the magnesia used in the frit to a minimum.

A soft surface is always the outcome of a mixing which can be fused at a low temperature. It is due to too much lead or an insufficiency of clay or silica powder.

A hard surface is due to the quantity of lead in the mixing being too small. Increase the quantity and introduce potash, say about 2.5 per cent.

The gray or fundamental mixing should be kept together in a condition only just sufficiently liquid to allow of being poured out. When required to be applied to the plate, the water necessary to lower it to the consistency of thick cream can then be added gradually, energetic stirring of the mass taking place simultaneously in order to obtain uniform distribution.

The time required for fusion may vary from 15 minutes to 25 minutes, but should never exceed the latter. If it does, it shows that the mixing is too viscous, and the remedy would be the addition and thorough intermixture of calcined borax or boracic acid. Should this fail, then remelting or a new frit is necessary.

A highly glazed surface on leaving the muffle shows that the composition is too fluid and requires the addition of clay, glass, silica powder or other substance to increase the viscosity.

As has been already explained, the glaze is much more important than the fundamental coating. Discoloration or slight flaws which could be tolerated in the latter would be fatal to the former.

[303]

ENAMELING

In glazes, oxide of lead need not be used. It should never be used in a coating for vessels which are to contain acids or be used as cooking utensils. It may be used in sign-tablet production.

For pipes the following glaze gives good results:

I.

Feldspar 33 percent

Borax 22.5 percent

Quartz 16.5 percent

Oxide of tin 15 percent

Soda 8 percent

Fluorspar 3.75 per cent

Saltpeter 2.25 percent

For sign tablets the following gives fair results, although some of the succeeding ones are in more general use:

II.

Gullet 20 per cent

Powdered flint 15 per cent

Lead 52 per cent

Soda 4.5 percent

Arsenic 4.5 per cent

Niter 4 per cent

III.

Frit of silica powder 30 per cent

Oxide of tin 18 percent

Borax 17 per cent

Soda 8.6 per cent

Niter 7.5 percent

White lead 5.5 per cent

Carbonate of ammonia 5.5 per cent

Magnesia 4 per cent

Silica powder 4 per cent

The following are useful for culinary utensils, as they do not contain lead:

IV.

Frit of silica powder 26 percent

Oxide of tin 21 per cent

Borax 20 per cent

Soda 10.25 per cent

Niter 7 per cent

Carbonate of ammonia 5 per cent

Magnesia 3.25 per cent

This should be ground up with the following:

Silica powder 4.25 per cent

Oxide of tin 2.25 per cent

Soda 0.5 per cent

Magnesia 0.5 per cent

V.

Feldspar 41 per cent

Borax 35 per cent

Oxide of tin 17 percent

Niter 7 per cent

VI.

Borax 30 per cent

Feldspar 22 per cent

Silicate powder 17.5 per cent

Oxide of tin 15 per cent

Soda 13.5 per cent

Niter 2 per cent

Borax will assist fusion. Quartz mixings require more soda than feldspar mixings.

VII.

Borax 28 per cent

Oxide of tin 19.5 per cent

Gullet (powdered white glass) 18 per cent

Silica powder 17.5 per cent

Niter 9.5 per cent

Magnesia 5 per cent

Clay 2.5 per cent

VIII.

Borax 26.75 per cent

Gullet 19 per cent

Silica powder 18.5 per cent

Oxide of tin 19 percent

Niter 9.25 per cent

Magnesia 4.5 per cent

Soda 3 per cent

To No. VII must be added while being ground the following percentages

of the weight of the frit:

Silica powder 18 per cent

Borax 9 per cent

Magnesia 5.25 per cent

Boracic acid 1.5 per cent

To No. VIII should be similarly added the following percentages of the frit:

Silica powder 1.75 per cent

Magnesia 1.75 per cent

Soda 1 per cent

This mixing is one which is used in the production of some of the best types of hollow ware for culinary purposes. The glaze should be kept in tubs mixed with water until used, and it should be carefully protected from dust.

Defects in the Glaze or White. A bad white may be due to its being insufficiently opaque. More oxide of tin is required. Cracks may be prevented by the addition of carbonate of ammonia. Insufficient luster can be avoided by adding to the quantity of soda and reducing the borax. If the gray shows through the white it proves that the temperature of fusion is too high or the viscosity of the mixing is too great. If the coating is not uniformly spread it may be due to the glaze being too thin; add magnesia. If the glaze separates from the gray add some bitter salt. Viscosity will be increased by reducing the quantity of borax. Immunity against chemical reaction is procured by increasing the quantity of borax. An improved luster will be obtained by adding native carbonate of soda. The greater the quantity of silicic acid the greater must be the temperature for fusion. To reduce the temperature add borax. Clay will increase the difficulty

[304]

ENAMELING

of fusion. Oxide of lead will make a frit more easily fusible. A purer white can be obtained by adding a small quantity of smalt.

Water. The character of the water used in the mixing of enamels is too frequently taken for granted, for unsuitable water may render a mixing almost entirely useless. Clean water, and with little or no sulphur present, is essential. For very fine enamels it is advisable to use carefully filtered water which has shown, after analysis, that it is free from any matter which is injurious to any of the enamel constituents.

How to Tell the Character of Enamel. In the case of sign tablets the characteristics looked to are appearance and the adherence of the coatings to the iron. For the latter the tests are simple. The plate if slightly bent should not crack the coating. An enamel plate placed in boiling water for some time and then plunged into very cold water should not show any cracks, however small, even after repeated treatment of this kind.

Culinary utensils, and those to hold chemicals, should not only look well, but should be capable of resisting the action of acids. Lead should never enter into the composition of enamels of this class, as they then become easily acted upon, and in the case of chipping present a menace to health. The presence of lead is easily detected. Destroy the outside coating of the enamel at some spot by the application of strong nitric acid. Wash the part and apply a drop of ammonium

sulphide. If lead is present, the part will become almost black, but remains unchanged in color if it is absent.

Another simple test is to switch up an egg in a vessel and allow it to stand for about 24 hours. When poured out and rinsed with water a dark stain will remain if lead is present in the enamel. To test the power of chemical resistance is equally simple. Boil diluted vinegar in the vessel for several minutes, and if a sediment is formed and the luster and smoothness of the glaze destroyed or partially destroyed, it follows that it is incapable of resisting the attacks of acids for any length of time. There are several other tests adopted, but those given present little difficulty in carrying out, and give reliable results.

Wasters and Seconds: Repairing Old Articles. In all enameling there must be certain articles turned out which are defective, but the percentage should never be very great. The causes which most frequently tend to the production of wasters are new mixings and a temperature of fusion which is either too high or too low. There are two ways of disposing of defective articles, viz.: (1) Chipping off the bad spots, patching them up and selling them as "seconds"; (2) throwing the articles into the waste heap. The best firms adopt the latter course, because the recoating and firing of defective parts practically means a repetition of the whole process, thus adding greatly to the cost, while the selling price is reduced. Overheating in fusion is generally shown by blisters or by the enamel being too thin in various places. Chipping may be also due to this cause, the excessive heat having practically fused the fundamental coating.

At this stage the defects may be remedied by breaking off the faulty parts, patching them up, and then recoating the whole. With sign tablets there is no objection to doing so, but with hollow ware the fact remains that the article is faulty, no matter how carefully defects may be hidden. As white is the most general coating used, and shows up the defects more than the colored coatings, the greatest care is necessary at every stage of the manufacture. While glowing on the article, it should appear uniformly yellow, but on cooling it should revert to a pure white shade. On examining different makes of white coated articles, it will be found that some are more opaque than others. The former are less durable than the latter, because they contain a large percentage of oxide of tin, which reduces the elasticity. To ensure hardness the mixing must be very liquid, and this cannot be arrived at when a large quantity of oxide of tin is introduced.

Old utensils which have become broken or chipped can be repaired, although, except in the case of large articles, this is rarely done. The operations necessary are: (1) The defective parts chipped off; (2) submitted to a red neat for a few moments; (3) coated with gray on the exposed iron; (4) fused; (5) coated with the glaze on the gray; (6) fused.

To Repair Enameled Signs.

Copal 5 parts

Damar 5 parts

Venice turpentine 4 parts

Powder the rosins, mix with the turpentine and add enough alcohol to form a thick liquid. To this add finely powdered zinc white in sufficient quantity to yield a plastic mass. Coloring

[305]

ENAMELING

matter may, of course, be added if desired.

The mass after application is polished when it has become sufficiently hard.

Enamel for Copper Cooking Vessels. White fluorspar is ground to a fine

powder and strongly calcined with an equal volume of unburnt gypsum, at a light glowing heat, stirring diligently. Grind the mixture to a paste with water, paint the vessel with it, using a brush, or pour in the paste like a glaze and dry the same. Increase the heat gradually and bring the vessels with the glass substance quickly into strong heat, under a suitable covering or a mantle of burnt clay. The substance soon forms a white opaque enamel, which ahderes [sic.] firmly to the copper. It can stand pretty hard knocks without cracking, is adapted for cooking purposes and not attacked by acid matters. If the glassy substance is desired to cling well and firmly to the copper, a sudden and severe heat must be observed.

To Pickle Black Iron Plate Scrap Before Enameling. The black iron-plate scraps are first dipped clean in a mixture of about 1 part of sulphuric acid and 20 to 22 parts of water heated to 30 to 40 C. (86 to 104º F.), and sharp quartz sand is then used for scouring. They are then plunged for a few seconds in boiling water, taken out, and allowed to dry. Rinsing with cold water and allowing to dry thus may cause rust. The grains of quartz cut grooves in the fibers of the iron; this helps the grounding to adhere well. With many kinds of plate it is advisable to anneal after pickling, shutting off the air; by this means the plates will be thoroughly clean and free from oxidation. Much practice is required. The Engineer.

ENAMELED IRON RECIPES.

The first thing is to produce a flux to fuse at a moderate heat, which, by flowing upon the plate, forms a uniform surface for the white or colored enamels to work upon.

Flux for Enameled Iron.

White lead 10 parts

Ball clay 1 part

Flint glass 10 parts

Whiting 1 part

The plates may then be coated with any of the following mixtures, which

may either be spread on as a powder with a little gum, as in the case of the flux, or the colors may be mixed with oil and the plates dipped therein when coated; the plate requires heating sufficiently to run the enamels bright.

Soft Enamels for Iron, White.

Flint glass 16 parts

Oxide of tin 1 1/2 parts

Niter 1 1/2 parts

Red lead 4 parts

Flint or china clay 1 part

Black.

Red oxide of iron 1 1/4 parts

Carbonate of cobalt 1 1/4 parts

Red lead 6 parts

Borax 2 parts

Lynn sand 2 parts

Yellow Coral.

Chromate of lead 1 part

Red lead 2 3/4 parts

Flint 1 part

Borax 1/4 part

Canary.

Oxide of uranium 1 part

Red lead 4 1/2 parts

Flint 1 1/2 parts

Flint glass 1 part

Turquoise.

Red lead 40 parts

Flint glass 12 parts

Borax 16 parts

Flint 12 parts

Enamel white 14 parts

Oxide of copper 7 parts

Oxide of cobalt 1/4 part

Red Brown.

Calcined sulphate of iron 1 part

Flux No. 8 (see page 307) 3 parts

Mazarine Blue.

Oxide of cobalt 10 parts

Paris white 9 parts

Sulphate barytes 1 part

Fire the above at an intense heat and for use take

Above stain 1 part

Flux No. 8 (see page 307) 3 parts

Sky Blue.

Flint glass 30 parts

White lead 10 parts

Pearlash 2 parts

Common salt 2 parts

Oxide of cobalt 4 parts

Enamel, white 4 parts

Chrome Green.

Borax 10 parts

Oxide of chrome 4 1/2 parts

White lead 9 parts

Flint glass 9 parts

Oxide of cobalt 2 parts

Oxide of tin 1 part

[306]

ENAMELING

Coral Red.

Bichromate potash 1 part

Red lead 4 1/2 parts

Sugar of lead 1 1/2 parts

Flint 1 1/2 parts

Flint glass 1 part

Enamel White. Soft:

Red lead 80 parts

Opal glass 50 parts

Flint 50 parts

Borax 24 parts

Arsenic 8 parts

Niter 6 parts

Enamel White.

Red lead 10 parts

Flint 6 parts

Boracic acid 4 parts

Niter 1 part

Soda crystals 1 part

Where the enameled work is intended to be exposed to the weather do not use flux No. 8, but substitute the following:

White lead 1 part

Ground flint glass 1 part

All the enamels should, after being mixed, be melted in crucibles, poured out when in liquid, and powdered or ground for use.

FUSIBLE ENAMEL COLORS.

The following colors are fusible by heat, and are all suitable for the decoration of china and glass. In the followng collection of recipes certain terms are employed which may not be quite understood by persons who are not connected with either the glass or porcelain industries, such as "glost fire" and "run down," and in such cases reference must be made to the following definitions:

"Run down." Sufficient heat to melt into liquid.

"Glost fire." Ordinary glaze heat.

"Grind only." No calcination required.

"Hard fire." Highest heat attainable.

"Frit." The ingredients partly composing a glaze, which require calcination.

"Stone." Always best Cornwall stone.

"Paris white." Superior quality of whiting.

"Parts." Always so many parts by weight, unless otherwise stated.

"D.L. Zinc." Particular brand not essential. Any good quality oxide of zinc will do.

Ruby and Maroon. Preparation of silver:

Nitric acid 1 ounce

Water 1 ounce

Dissolve the silver till saturated, then put a plate of copper in the solution to precipitate the silver in a metallic state. Wash well with water to remove the acetate of copper.

Flux for Above. Six dwts. white lead to 1 ounce prepared silver.

Tin Solution. Put the acid (aqua regia) in a bottle, add tin in small quantities until it becomes a dark-red color; let it stand about 4 days before use. When the acid becomes saturated it will turn red at the bottom of the bottle, then shake it up and add more tin; let it stand and it will become clear.

Aqua Regia.

Nitric acid 2 parts

Muriatic acid 1 part

Dissolve grain gold in the aqua regia so as to make a saturated solution. Take a basin and fill it 3 parts full of water; drop the solution of gold into it till it becomes an amber color. Into this solution of gold gradually drop the solution of tin, until the precipitate is complete. Wash the precipitate until the water becomes tasteless, then dry slowly and flux as follows:

Flux No. I.

Borax 3 parts

Red lead 3 parts

Flint 2 parts

Run down.

Rose Mixture.

Purple of Cassius 1 ounce

Flux No. 1 6 ounces

Prepared silver 3 dwts.

Flint glass 2 ounces

Grind.

Purple Mixture.

Purple of Cassius 1 ounce

Flux No. 8 (see page 307) 2 1/2 ounces

Flint glass 2 ounces

Grind.

Ruby.

Purple mixture 2 1/2 parts

Rose mixture 1 1/2 part

Grind.

Maroon.

Rose mixture 1 part

Purple mixture 2 parts

Grind.

[307]

ENAMELING

Black Extra quality.

Red oxide of iron 12 parts

Carbonate of cobalt 12 parts

Oxide of cobalt 1 part

Black flux A (see next formula) 80 parts

Glost fire.

Black Flux A.

Red lead 3 parts

Calcined borax 1/2 part

Lynn sand 1 part

Run down.

Black No. 2.

Oxide of copper 1 part

Carbonate of cobalt 1/2 part

Flux No. 8 (see next column) 4 parts

Grind only.

Enamel White.

Arsenic 2 1/2 parts

Niter 1 1/2 parts

Borax 4 parts

Flint 16 parts

Glass 16 parts

Red lead 32 parts

Glost fire.

Turquoise. China:

Calcined copper 5 parts

Whiting 5 parts

Phosphate of soda 8 parts

Oxide of zinc 16 parts

Soda crystals 4 parts

Magnesia 2 parts

Red lead 8 parts

Flux T (see next formula) 52 parts

Glost fire.

Flux T.

Borax 2 parts

Sand 1 part

Run down.

Orange.

Orange U.G. 1 part

Flux No. 8 (see next column) 3 parts

Grind only.

Blue Green.

Flint glass 8 parts

Enamel white 25 parts

Borax 8 parts

Red lead 24 parts

Flint 6 parts

Oxide of copper 2 1/2 parts

Glost heat.

Coral Red.

Chromate of potash 1 part

Sugar of lead 1 1/3 parts

Dissolve in hot water, then dry. Take 1 part of above, 3 parts flux for coral. Grind.

Flux for Coral.

Red lead 4 1/2 parts

Flint 1 1/2 parts

Flint glass 1 1/2 parts

Run down.

Turquoise.

Oxide of copper 5 parts

Borax 10 parts

Flint 12 parts

Enamel white 14 parts

Red lead 40 parts

Glost fire.

Flux No. 8.

Red lead 6 parts

Borax 4 parts

Flint 2 parts

Run down.

Russian Green.

Malachite green 10 parts

Enamel yellow 5 parts

Majolica white 5 parts

Flux No. 8 (see previous formula) 2 parts

Grind only.

Amber.

Oxide of uranium 1 part

Coral flux 8 parts

Grind only.

Gordon Green.

Yellow U.G. 5 parts

Flux No. 8 (see above) 15 parts

Malachite green 10 parts

Grind only.

Celadon.

Enamel light blue 1 part

Malachite green 1 part

Flux No. 8 (see above) 15 parts

Grind only.

Red Brown.

Sulphate of iron, fired 1 part

Flux No. 8 (see above) 3 parts

Grind only.

Matt Blue.

Flux No. 8 (see above) 10 1/2 parts

Oxide of zinc 5 parts

Oxide of cobalt 4 parts

Glost fire, then take

Of above base 1 part

Flux No. 8 (see above) 1 1/8 parts

Grind only.

[308]

ENAMELING

PREPARATION OF ENAMELS.

The base of enamel is glass, colored different shades by the addition of metallic oxides mixed and melted with it.

The oxide of cobalt produces blue; red is obtained by the Cassius process. The purple of Cassius, which is one of the most brilliant of colors, is used almost exclusively in enameling and miniature painting; it is produced by adding to a solution of gold chloride a solution of tin chloride mixed with ferric chloride until a green color appears. The oxide of iron and of copper also produces red, but of a less rich tone; chrome produces green, and manganese violet; black is produced by the mixture of these oxides. Antimony and arsenic also enter into the composition of enamels.

Enamels are of two classes opaque and transparent. The opacity is caused by the presence of tin.

When the mingled glass and oxides have been put in the crucible, this is placed in the furnace, heated to a temperature of 1,832º or 2,200º F. When the mixture becomes fused, it is stirred with a metal rod. Two or three hours are necessary for the operation. The enamel is then poured into water, which divides it into grains, or formed into cakes or masses, which are left to cool.

For applying enamels to metals, gold, silver, or copper, it is necessary to reduce them to powder, which is effected in an agate mortar with the aid of a pestle of the same material. During the operation the enamel ought to be soaked in water.

For dissolving the impurities which may have been formed during the work, a few drops of nitric acid are poured in immediately afterwards, well mixed, and then got rid of by repeated washing with filtered water. This should be carefully done, stirring the enamel powder with a glass rod, in order to keep the particles in suspension.

The powder is allowed to repose at the bottom of the vessel, after making sure by the taste of the water that it does not contain any trace of acid; only then is the enamel ready for use.

For enameling a jewel or other object it is necessary, first to heat it strongly, in order to burn off any fatty matter, and afterwards to cleanse it in a solution of nitric acid diluted with boiling water.

After rinsing with pure water and wiping with a very clean cloth, it is heated slightly and is then ready to receive the enamel.

Enamels are applied with a steel tool in the form of a spatula; water is the vehicle. When the layers of enamel have been applied, the contained water is removed by means of a fine linen rag, pressing slightly on the parts that have received the enamel. The tissue absorbs the water, and nothing remains on the object except the enamel powder.

It is placed before the fire to remove every trace of moisture. Thus prepared and put on a fire-clap slab, it is ready for its passage to the heat which fixes the enamel. This operation is conducted in a furnace, with a current of air whose temperature is about 1,832º F. In this operation the fire-chamber ought not to contain any gas.

Enamels are fused at a temperature of 1,292º to 1,472º F. Great attention is needed, for experience alone is the guide, and the duration of the process is quite short. On coming from the fire, the molecules composing the enamel powder have been fused together and present to the eye a vitreous surface covering the metal and adhering to it perfectly. Under the action of the heat the metallic oxides contained in the enamel have met the oxide of the metal and formed one body with it, thus adhering completely.

JEWELERS' ENAMELS.

Melt together:

Transparent Red. Cassius gold purple, 65 parts, by weight; crystal glass, 30 parts, by weight; borax, 4 parts, by weight.

Transparent Blue. Crystal glass, 34 parts, by weight; borax, 6 parts, by weight; cobalt oxide, 4 parts, by weight.

Dark Blue. Crystal glass, 30 parts, by weight; borax, 6 parts, by weight; cobalt oxide, 4 parts, by weight; bone black, 4 parts, by weight; arsenic acid, 2 parts, by weight.

Transparent Green. Crystal glass, 80 parts, by weight; cupric oxide, 4 parts, by weight; borax, 2 parts, by weight.

Dark Green. Crystal glass, 30 parts, by weight; borax, 8 parts, by weight; cupric oxide, 4 parts, by weight; bone black, 4 parts by weight; arsenic acid, 2 parts, by weight.

Black. Crystal glass, 30 parts, by weight; borax, 8 parts, by weight; cupric oxide, 4 parts, by weight; ferric oxide, 3 parts, by weight; cobalt oxide, 4 parts, by weight; manganic oxide, 4 parts, by weight.

White.

I. Crystal glass, 30 parts, by weight; stannic oxide, 6 parts, by weight; borax, 6 parts, by weignt; arsenic acid, 2 parts, by weight.

II. Crystal glass, 30 parts, by weight; sodium antimonate, 10 parts, by weight.

309

ENAMELING - ENGRAVINGS

The finely pulverized colored enamel is applied with a brush and lavender oil on the white enamel already fused in and then only heated until it melts. For certain purposes, the color compositions may also be fused in without a white ground. The glass used for white, No. 2, must be free from lead, otherwise the enamel will be unsightly.

Various Enamels for Precious Metals:

White. Crystal glass, 30 parts, by weight; oxide of tin, 6 parts, by weight; borax, 6 parts, by weight; dioxide of arsenic, 2. parts, by weight, or silicious sand, 50 parts, by weight; powder, consisting of 15 of tin per 100 of lead, 100 parts, by weight; carbonate of otassium,

40 parts, by weight. Fuse the whole with a quantity of manganese. To take away the accidental coloring, pour it into water, and after having pulverized it, melt again 3 or 4 times.

Opaque Blue. Crystal glass, 30 parts, by weight; borax, 6 parts, by weight; cobalt oxide, 4 parts, by weight; calcined bone, 4 parts, by weight; dioxide of arsenic, 2 parts, by weight.

Transparent Green. Crystal glass, 30 parts, by weight; blue verditer, 4 parts, by weight; borax, 2 parts, by weight.

Opaque Green. Crystal glass, 30 parts, by weight; borax, 8 parts, by weight; blue verditer, 4 parts, by weight; calcined bone, 4 parts, by weight; dioxide of arsenic, 2 parts, by weight.

Black. I. Crystal glass, 30 parts, by weight; borax, 8 parts, by weight; oxide of copper, 4 parts, by weight; oxide of iron, 3 parts, by weight; oxide of cobalt, 4 parts, by weight; oxide of manganese,

4 parts, by weight.

II. Take 1/2 part, by weight, of silver; 2 1/2 parts of copper; 3 1/2 parts of lead, and 2 1/2 parts of muriate of ammonia. Melt together and pour into a crucible with twice as much pulverized sulphur; the crucible is then to be immediately covered that the sulphur may not take fire, and the mixture is to be calcined over a smelting fire until the superfluous sulphur is burned away. The compound is then to be coarsely pounded, and, with a solution of muriate of ammonia, to be formed into a paste which is to be placed upon the article it is designed to enamel. The article must then be held over a spirit lamp till the compound upon it melts and flows. After this it may be smoothed and polished up in safety.

See also Varnishes and Ceramics for other enamel formulas.

ENAMEL COLORS, QUICK DRYING:

See Varnishes.

ENAMEL REMOVERS:

See Cleaning Preparations and Methods.

ENAMELING ALLOYS:

See Alloys.

ENGINES (GASOLINE), ANTI-FREEZING SOLUTION FOR:

See Freezing Preventives.

ENGRAVING SPOON HANDLES.

After the first monogram has been engraved, rub it with a mixture of 3 parts of beeswax, 3 of tallow, 1 of Canada balsam, and 1 of olive oil. Remove any superfluous quantity, then moisten a piece of paper with the tongue, and press it evenly upon the engraving. Lay a dry piece of paper over it, hold both firmly with thumb and forefinger of left hand, and rub over the surface with a polishing tool of steel or bone. The wet paper is thereby pressed into the engraving, and, with care, a clear impression is made. Remove the paper carefully, place it in the same position on another handle, and a clear impression will be left. The same paper can be used 2 dozen times or more.

ENGRAVING ON STEEL:

See Steel.

Engravings: Their Preservation

(See also Pictures, Prints, and Lithographs.)

Cleaning of Copperplate Engravings. Wash the sheet on both sides by means of a soft sponge or brush with water to which 40 parts of ammonium carbonate has been added per 1,000 parts of water, and rinse the paper each time with clear water. Next moisten with water in which a little wine vinegar has been admixed, rinse the sheet again with water containing a little chloride of lime, and dry in the air, preferably in the sun. The paper will become perfectly clear without the print being injured.

Restoration of Old Prints. Old engravings, woodcuts, or printed sheets that have turned yellow may be rendered white by first washing carefully in water containing a little hyposulphite of soda, and then dipping for a minute in javelle water. To prepare the latter, put 4 pounds of bicarbonate of soda in a pan, pour over it 1 gallon of boiling water; boil for 15 minutes, then stir in 1

[310]

ENGRAVINGS - ESSENCES AND EXTRACTS

pound of chloride of lime. When cold, pour off the clear liquid, and keep in a jug ready for use.

Surprising results are obtained from the use of hydrogen peroxide in the restoration of old copper or steel engravings or lithographs which have become soiled or yellow, and this without the least injury to the picture. The cellulose which makes the substance of the paper resists the action of ozone, and the black carbon color of these prints is indestructible.

To remove grease or other spots of dirt before bleaching, the engravings are treated with benzine. This is done by laying each one out flat in a shallow vessel and pouring the benzine over it. As

benzine evaporates very rapidly, the vessel must be kept well covered, and since its vapors are also exceedingly inflammable, no fire or smoking should be allowed in the room. The picture is left for several hours, then lifted out and dried in the air, and finally brushed several times with a soft brush. The dust which was kept upon the paper by the grease now lies more loosely upon it and can easily be removed by brushing.

In many cases the above treatment is sufficient to improve the appearance of the picture. In the case of very old or badly soiled engravings, it is followed by a second, consisting in the immersion of the picture in a solution of sodium carbonate or a very dilute solution of caustic soda, it being left as before for several hours. After the liquid has been poured off, the picture must be repeatedly rinsed in clear water, to remove any remnant of the soda.

By these means the paper is so far cleansed that only spots of mold or other discolorations remain. These may be removed by hydrogen peroxide, in a fairly strong solution. The commercial peroxide may be diluted with 2 parts water.

The picture is laid in a shallow vessel, the peroxide poured over it, and the vessel placed in a strong light. Very soon the discolorations will pale.

To Reduce Engravings. Plaster casts, as we know, can be perceptibly reduced in size by treatment with water or alcohol, and if this is properly done, the reduction is so even that the cast loses nothing of its clear outline, but sometimes even gains in this respect by contraction. If it is desired to reduce an engraved plate, make a plaster cast of it, treat this with water or alcohol, and fill the new cast with some easily fusible metal. This model, which will be considerably smaller than the original, is to be made again in plaster, and again treated, until the desired size is reached. In this way anything of the kind, even medallions, can be reproduced on a smaller scale.

ENLARGEMENTS:

See Photography.

ENVELOPE GUM:

See Adhesives, under Mucilages.

EPIZOOTY:

See Veterinary Formulas.

Essences and Extracts of Fruits

Preservation of Fruit Juices. The juices of pulpy fruits, when fresh, contain an active principle known as pectin, which is the coagulating substance that forms the basis of fruit jellies. This it is which prevents the juice of berries and similar fruits from passing through filtering media. Pectin may be precipitated by the addition of alcohol, or by fermentation. The latter is the best, as the addition of alcohol to the fresh juices destroys their aroma and injures the taste. The induction of a light fermentation is far the better method, not only preserving, when carefully conducted, the taste and aroma of the fruit, but yielding far more juice. The fruit is crushed and the juice subsequently carefully but strongly pressed out. Sometimes the crushed fruit is allowed to stand a while, and to proceed to a light fermentation before pressure is applied; but while a greater amount of juice is thus obtained, the aroma and flavor of the product are very sensibly injured by the procedure.

To the juice thus obtained, add from 1 to 2 per cent of sugar, and put away in a cool place (where the temperature will not rise over 70º or 75º F.). Fermentation soon begins, and will proceed for a few days. As soon as the development of carbonic acid gas ceases, the juice begins to clear itself, from the surface downward, and in a short time all solid matter will lie in a mass at the bottom, leaving the liquid bright and clear. Draw off the latter with a siphon, very carefully, so as not to disturb the sedimentary matter. Fermentation should be induced in closed vessels only, as when conducted in open containers a fungoid growth is apt to form on the surface, sometimes causing putrefactive, and at others, an acetic, fermentation, in either event spoiling the juice for sub-

[311]

ESSENCES AND EXTRACTS

sequent use, except as a vinegar. The vessels, to effect the end desired, should be filled only two-thirds or three-fourths full, and then carefully closed with a tight-fitting cork, through which is passed a tube of glass, bent at the upper end, the short end of which passes below the surface of a vessel filled with water. As soon as fermentation commences the carbonic acid developed thereby escapes through the tube into the water, whence it passes off into the atmosphere. When bubbles no longer pass off from the tube the operation should be interrupted, and decantation or siphoning, with subsequent filtration, commenced.

By proceeding in this manner all the aroma and flavor of the juices are retained. If it is intended for preservation for any length of time the juice should be heated on a water bath to about 176º F. and poured, while hot, into bottles which have been asepticized by filling with cold water, and placing in a vessel similarly filled, bringing to a boiling temperature, and maintaining at this temperature until the juice, while still hot, is poured into them. If now closed with corks similarly asepticized, or by dipping into hot melted paraffine, the juice may be kept unaltered for years. It is better, however, to make the juice at once into syrup, using the best refined sugar, and boiling in a copper kettle (iron or tin spoil the color), following the usual precautions as to skimming, etc. The syrup should be poured hot into the bottles previously heated as before described.

Ripe fruit may be kept in suitable quantities for a considerable time if covered with a solution of saccharine and left undisturbed, this, too, without deteriorating the taste, color, or aroma of the fruit if packed with care.

Whole fruit may be stored in bulk, by carefully and without fracture filling into convenient-sized jars or bottles, and pouring thereon a solution containing a quarter of an ounce of refined saccharine to the gallon of water, so filling each vessel that the solution is within an inch of the cork when pressed into position. The corks should first of all be immersed in melted paraffine wax, then drained, and allowed to cool. When fruit juices alone are required for storage purposes they are prepared by subjecting the juicy fruits to considerable pressure, by which process the juices are liberated.

The sound ripe fruits are crushed and packed into felt or flannel bags. The fruit should be carefully selected, rotten or impaired portions being carefully removed; this is important, or the whole stock would be spoiled. Several methods are adopted for preserving and clarifying fruit juices.

A common way in which they are kept from fermenting is by the use of salicylic acid or other antiseptic substance, which destroys the fermentative germ, or otherwise retards its action for a considerable time. The use of this acid is seriously objected to by some as injurious to the consumer. About 2 ounces of salicylic acid, previously dissolved in alcohol, to 25 gallons of juice, or 40 grains to the gallon, is generally considered the proper proportion.

Another method adopted is to fill the freshly prepared cold juice into bottles until it reaches the necks, and on the top of this fruit juice a little glycerine is placed.

Juices thus preserved will keep in an unchanged condition in any season. Probably one of the best methods of preserving fruit juices is to add 15 per cent of 95 per cent alcohol. On such an addition, albumen and mucilaginous matter will be deposited. The juice may then be stored in large bottles, jars, or barrels, if securely closed, and when clear, so that further clarification is unnecessary, the juice should finally be decanted or siphoned off.

A method applicable to most berries is as follows:

Take fresh, ripe berries, stem them, and rub through a No. 8 sieve, rejecting all soft and green fruit. Add to each gallon of pulp thus obtained 8 pounds of granulated sugar. Put on the fire and bring just to a boil, stirring constantly. Just before removing from the fire, add to each gallon 1 ounce of a saturated alcoholic solution of salicylic acid, stirring well. Remove the scum, and, while still hot, put into jars and hermetically seal. Put the jars in cold water, and raise them to the boiling point, to prevent them from bursting by sudden expansion on pouring hot fruit into them. Fill the jars entirely full, so as to leave no air space when fruit cools and contracts.

Prevention of Foaming and Partial Caramelization of Fruit Juices. Fresh

fruit juices carry a notable amount of free carbonic acid, which must make its escape on heating the liquid. This will do easily enough if the juice be heated in its natural state, but the addition of the sugar so increases the density of the fluid that the acid finds escape difficult, and often the result is foaming. As to the burning or partial caramelization of

[312]

ESSENCES AND EXTRACTS

the syrup, that is easily accounted for in the greater density of the syrup at the bottom of the kettle the lighter portion, or that still carrying imprisoned gases, remaining on top until it is freed from them. Constant stirring can prevent this only partially, since it cannot entirely overcome the results of the natural forces in action. The consequence is more or less caramelization. The remedy is very simple. Boil the juices first, adding distilled water to make up for the loss by evaporation, and add the sugar afterwards.

ESSENCES AND EXTRACTS:

Almond Extracts.

I. Oil of bitter almonds 90 minims Alcohol, 94 per cent, quantity sufficient to make 8 ounces.

II.

Oil of bitter almonds 80 minims

Alcohol 7 ounces

Distilled water, quantity sufficient to make 8 ounces.

III.

Oil of bitter almonds, deprived

of its hydrocyanic acid 1 ounce

Alcohol 15 ounces

In order to remove the hydrocyanic acid in oil of bitter almonds, dissolve 2 parts of ferrous sulphate in 16 parts of distilled water; in another vessel slake 1 part freshly burned quicklime in a similar quantity of distilled water, and to this add the solution of iron sulphate, after the same has cooled. In the mixture put 4 parts of almond oil, and thoroughly agitate the liquids together. Repeat the agitation at an interval of 5 minutes, then filter. Put the filtrate into a glass retort and distil until all the oil has passed over. Remove any water that may be with the distillate by decantation, or otherwise.

Apricot Extract.

Linalyl formate 90 minims

Glycerine 1 ounce

Amyl valerianate 4 drachms

Alcohol 11 ounces

Fluid extract orris 1 ounce

Water, quantity sufficient to make 1 pint

Apple Extract.

Glycerine 1 ounce

Amyl valerianate 4 drachms

Linalyl formate 45 minims

Fluid extract orris 1 ounce

Alcohol 11 ounces

Water, quantity sufficient to make 1 pint

Apple Syrup.

I. Peel and remove the cores of, say, 5 parts of apples and cut them into little bits. Put in a suitable vessel and pour over them a mixture of 5 parts each of common white wine and water, and let macerate together for 5 days at from 125º to 135º F., the vessel being closed during the time. Then strain the liquid through a linen cloth, using gentle pressure on the solid matter, forcing as much as possible of it through the cloth. Boil 30 parts of sugar and 20 parts of water together, and when boiling add to the resulting syrup the apple juice; let it boil up for a minute or so, and strain through flannel.

II. Good ripe apples are cut into small pieces and pounded to a pulp in a mortar of any metal with the exception of iron. To 1 part of this pulp add 11 parts of water. Allow this to stand for 12 hours. Colate. To 11 parts of the colature add 1 part of sugar. Boil for 5 minutes. Skim carefully. Bottle slightly warm. A small quantity of tartaric acid may be added to heighten the flavor.

Banana Syrup. Cut the fruit in slices and place in a jar; sprinkle with sugar and cover the jar, which is then enveloped in straw and placed in cold water and the latter is heated to the boiling point. The jar is then removed, allowed to cool, and the juice poured into bottles.

Cinnamon Essence.

Oil of cinnamon 2 drachms

Cinnamon, powdered 4 ounces

Alcohol, deodorized 16 ounces

Distilled water 16 ounces

Dissolve the oil in the alcohol, and add the water, an ounce at a time, with agitation after each addition. Moisten the cinnamon with a little of the water, add, and agitate. Cork tightly, and put in a warm place, to macerate, 2 weeks, giving the flask a vigorous agitation several times a day. Finally, filter through paper, and keep in small vials, tightly stoppered.

Chocolate Extract. Probably the best form of chocolate extract is made as follows:

Curacao cocoa 400 parts

Vanilla, chopped fine 1 part

Alcohol of 55 per cent 2,000 parts

Mix and macerate together for 15 days, express and set aside. Pack the residue in a percolator, and pour on boiling water (soft) and percolate until 575 parts pass through. Put the percolate

[313]

ESSENCES AND EXTRACTS

in a flask, cork, and let cool, then mix with the alcoholic extract. If it be desired to make a syrup, before mixing the extract, add 1,000 parts of sugar to the percolate, and with gentle heat dissolve the sugar. Mix the syrup thus formed, after cooling, with the alcoholic extract.

Coffee Extracts. In making coffee extract, care must be used to avoid extracting the bitter properties of the coffee, as this is where most manufacturers fail; in trying to get a strong extract they succeed only in getting a bitter one.

I. The coffee should be a mixture of Mocha, 3 parts; Old Government Java, 5 parts; or, as some prefer, Mocha, 3 parts; Java, 3 parts; best old Rio, 2 parts.

Coffee, freshly roasted and pulverized 100 parts

Boiling water 600 parts

Pack the coffee, moistened with boiling water, in a strainer, or dipper, placed in a vessel standing in the water bath at boiling point, and let 400 parts of the water, in active ebullition, pass slowly through it. Draw off the liquid as quickly as possible (best into a vessel previously heated by boiling water to nearly the boiling point), add 200 parts of boiling water, and pass the whole again through the strainer (the container remaining in the water bath). Remove from the bath; add 540 parts of sugar, and dissolve by agitation while still hot.

II. The following is based upon Liebig's method of making coffee for table use: Moisten 50 parts of coffee, freshly roasted and powdered as before, with cold water, and add to it a little egg albumen and stir in. Pour over the whole 400 parts of boiling water, set on the fire, and let come to a boil. As the liquid foams, stir down with a spoon, but let it come to a boil for a moment; add a little cold water, cover tightly, and set aside in a warm place. Exhaust the residual coffee with 300 parts of boiling water, as detailed in the first process, and to the filtrate add carefully the now clarified extract, up to 600 parts, by adding boiling water. Proceed to make the syrup by the method detailed above.

III. To make a more permanent extract of coffee saturate 600 parts of freshly roasted coffee, ground moderately fine, with any desired quantity of a 1 in 3 mixture of alcohol of 94 per cent and distilled water, and pack in a percolator. Close the faucet and let stand, closely stoppered, for 24 hours; then pour on the residue of the alcohol and water, and let run through, adding sufficient water, at the last, so as to compensate for what boils away. Set this aside, and continue the percolation, with boiling water, until the powder is exhausted. Evaporate the resultant percolate down to the consistency of the alcoholic extract, and mix the two. If desired, the result may be evaporated down to condition of an extract. To dissolve, add boiling water.

IV. This essence is expressly adapted to boiling purposes. Take 3 pounds of good coffee, 4 ounces of granulated sugar, 4 pints of pure alcohol, 6 pints of hot water. Have coffee fresh roasted and of a medium grinding. Pack in a glass percolator, and percolate it with a menstruum, consisting of the water and the alcohol. Repeat the percolation until the desired strength is obtained, or the coffee exhausted; then add the sugar and filter.

V.

Mocha coffee 1 pound

Java coffee 1 pound

Glycerine, quantity sufficient.

Water, quantity sufficient.

Grind the two coffees fine, and mix, then moisten with a mixture of 1 part of glycerine and 3 parts of water, and pack in a glass percolator, and percolate slowly until 30 ounces of the percolate is obtained. It is a more complete extraction if the menstruum be poured on in the condition of boiling, and it be allowed to macerate for 20 minutes before percolation commences. Coffee extract should, by preference, be made in a glass percolator. A glycerine menstruum is preferable to one of dilute alcohol, giving a finer product.

VI.

Coffee, Java, roasted, No. 20 powder 4 ounces

Glycerine, pure 4 fluidounces

Water, quantity sufficient.

Boiling, quantity sufficient.

Moisten the coffee slightly with water, and pack firmly in a tin percolator; pour on water, gradually, until 4 fluidounces are obtained, then set aside. Place the coffee in a clean tin vessel, with 8 fluidounces of water, and boil for 5 minutes. Again place the coffee in the percolator with the water (infusion), and when the liquid has passed, or drained off, pack the grounds firmly, and pour on boiling water until 8 fluidounces are obtained. When cold, mix the first product, and add the glycerine, bottle, and cork well.

The excellence of this extract of coffee, from the manner of its preparation, will be found by experience to be incomparably superior to that made by the for-

[314]

ESSENCES AND EXTRACTS

mulas usually recommended, the reason being apparent in the first step in the process.

Coffee Essence.

Best ground Mocha coffee 4 pounds

Best ground chicory 2 pounds

Boil with 2 gallons of water in a closed vessel and when cold, strain, press, and make up to 2 gallons, and to this add

Rectified spirit of wine 8 ounces

Pure glycerine (fluid) 16 ounces

Add syrup enough to make 4 gallons, and mix intimately.

Cucumber Essence. Press the juice from cucumbers, mix with an equal volume of alcohol and distil. If the distillate is not sufficiently perfumed, more juice may be added and the mixture distilled. It is said that the essence thus prepared will not spoil when mixed with fats in the preparation of cosmetics.

Fruit Jelly Extract. Fill into separate paper bags:

Medium finely powdered gelatin 18 parts

Medium finely powdered citric acid 3 parts

Likewise into a glass bottle a mixture of any desired

Fruit essence 1 part

Spirit of wine 1 part

and dissolve in the mixture for obtaining the desired color, raspberry red or lemon yellow, 1/10 part.

For use, dissolve the gelatin and the citric acid in boiling water, adding

Sugar 125 parts

and mixing before cooling with the fruit essence mixture.

Ginger Extracts. The following is an excellent method of preparing a soluble essence or extract of ginger:

I.

Jamaica ginger 24 ounces

Rectified spirits, 60 per cent 45 ounces

Water 15 ounces

Mix and let macerate together with frequent agitations for 10 days, then percolate, press off, and filter. The yield should be 45 ounces. Of this take 40 ounces and mix with an equal amount of distilled water. Dissolve 6 drachms of sodium phosphate in 5 ounces of boiling water; let cool and add the solution to the filtrate and water, mixing well. Add 2 drachms of calcium chloride dissolved in 5 ounces of water, nearly cold, and again thoroughly shake the whole. Let stand for 12 hours; then filter.

Put the filtrate in a still, and distil off, at as slow a temperature as possible, 30 ounces. Set this distillate to one side, and continue the distillation till another 40 ounces have passed, then let the still cool. The residue in the still, some 18 ounces, is the desired essence. Pour out all that is possible and wash the still with the 30 ounces of distillate first set aside. This takes up all that is essential.

Finally, filter once more, through double filter paper and preserve the filtrate about 40 ounces, of an amber-colored liquid containing all of the essentials of Jamaica ginger.

Soluble Essence of Ginger.

II. The following is Harrop's method of proceeding:

Fluid extract of ginger (U.S.) 4 ounces

Pumice, in moder-ately fine powder 1 ounce

Water enough to make 12 ounces

Pour the fluid extract into a bottle, add the pumice and shake the mixture and repeat the shaking in the course of several hours. Now add the water in proportion of about 2 ounces, shaking well and frequently after each addition. When all is added repeat the agitation occasionally during 24 hours, then filter, returning the last portion of the filtrate until it comes through clear, and if necessary add sufficient water to make 12 ounces.

III.

Jamaica ginger, ground 2 pounds

Pumice stone, ground 2 ounces

Lime, slaked 2 ounces

Alcohol, dilute 4 pints

Rub the ginger with the pumice stone and lime until thoroughly mixed. Moisten with the dilute alcohol until saturated and place in a narrow percolator, being careful not to use force in packing, but simply putting it in to obtain the position of a powder to be percolated, so that the menstruum will go through uniformly. Finally, add the dilute alcohol and proceed until 4 pints of percolate are obtained. Allow the liquid to stand for 24 hours; then filter if necessary.

IV.

Tincture ginger 480 parts

Tincture capsicum 12 parts

Oleoresin ginger 8 parts

Magnesium carbonate 16 parts

Rub the oleoresin with the magnesia, and add the tinctures; add about 400

[315]

ESSENCES AND EXTRACTS

parts of water, in divided portions, stirring vigorously the while. Transfer the mixture to a bottle, and allow to stand 1 week, shaking frequently; then filter, and make up 960 parts with water.

V.

Fluid extract of ginger (U.S.P.) 4 ounces

Pumice, powdered and washed 1 ounce

Water enough to make 12 ounces

Pour the fluid extract of ginger into a bottle, and add the pumice, shake thoroughly, set aside, and repeat the operation in the course of several hours. Add the water, in the proportion of about 2 ounces at a time, agitating vigorously after each addition. When all is added, repeat the agitation occasionally during 24 hours, then filter, returning the first portion of the filtrate until it comes through bright and clear. If necessary, pass water through the filter, enough to make 12 fluidounces of filtrate.

VI.

Strongest tincture of ginger 1 pint

Fresh slaked lime 1 1/2 ounces

Salt of tartar 1/4 ounce

VII.

Jamaica ginger, ground 32 parts

Pumice stone, powdered 32 parts

Lime, slaked 2 parts

Alcohol, dilute, sufficient to make 32 parts

Rub the ginger with the pumice stone and lime, then moisten with alcohol until it is saturated with it. Put in a narrow percolator, using no force in packing. Allow the mass to stand for 24 hours, then let run through. Filter if necessary.

VIII. The following is insoluble:

Cochin ginger, cut fine 1,000 parts

Alcohol, 95 per cent 2,500 parts

Water 1,250 parts

Glycerine 250 parts

Digest together for 8 days in a very warm, not to say hot, place. Decant, press off the roots, and add to the colature, then filter through paper. This makes a strong, natural tasting essence.

IX. Green Ginger Extract. The green ginger root is freed from the epidermis and surface dried by exposure to the air for a few hours. It is then cut into thin slices and macerated for some days with an equal weight of rectified spirit, which when filtered will yield an essence possessing a very fine aroma and forming an almost perfectly clear solution in water. If the ginger is allowed to dry more than the few hours mentioned it will not produce a soluble essence. It is used in some of the imported ginger ales as a flavoring only, and makes a lovely ginger flavor.

Hop Syrup. A palatable preparation not inferior to many of the so-called hop bitters:

Hops 2 parts

Dandelion 2 parts

Gentian 2 parts

Chamomile 2 parts

Stillingia 2 parts

Orange peel 2 parts

Alcohol 75 parts

Water 75 parts

Syrup, simple 50 parts

Coarsely powder the drugs and exhaust with the water and alcohol mixed.

Decant, press out and filter, and finally add the syrup. The dose is a wineglassful 2 or 3 times daily.

Lemon Essences.

I. Macerate the cut-up fresh peelings of 40 lemons and 30 China oranges in 8 quarts of alcohol and 2 quarts of water, for 2 or 3 days, then distil off 8 quarts. Every 100 parts of this distillate is mixed with 75 parts of citric acid dissolved in 200 parts of water, colored with a trace of orange and filtered through talc. Each 200 parts of the filtrate is then mixed with 2 quarts of syrup.

II. Twenty-five middle-sized lemons are thinly peeled, the peelings finely cut, and the whole, lemons and peels, put to macerate in a mixture of 3 pints 90 per cent alcohol and 5 quarts water. Let macerate for 24 hours. Add 10 drops lemon and 10 drops orange oil; then slowly distil off 4 quarts. The distillate will be turbid, but if left to stand in a cool, dark place for a week it will filter off clear, and should make a clear mixture with equal parts of water and simple syrup. If it does not, add with a pipette, drop by drop, sufficient alcohol to make it do so. Finally, dissolve in the mixture 4 drachms of vanillin, and color with a few drops of tincture of turmeric and a little caramel.

III. Peel thinly and lightly, 25 medium-sized fresh lemons and 1 orange, and cut the peelings into very small pieces. Macerate in 55 drachms 96 per cent alcohol, for 6 hours. Filter off the macerate without pressing. Dilute the filtrate with 3 pints water and set aside for eight days, shaking frequently. At

[316]

ESSENCES AND EXTRACTS

the end of this time filter. The filtrate is usually clear, and if so, ad 4 drachms of vanillin. If not, proceed as in the second formula above.

IV. Oil of lemon, select, 8 fluidounces; oil of lemon grass (fresh), 1 fluidrachm; peel, freshly grated, of 12 lemons; alcohol, 7 pints; boiled water, 1 pint.

Mix and macerate for 7 days. If in a hurry for the product, percolate through the lemon peel and filter. The addition of any other substance than the oil and rind of the lemon is not recommended.

V.

Fresh oil of lemon 64 parts

Lemon peel (outer rind) freshly grated 32 parts

Oil of lemon grass 1 part Alcohol 500 parts

Mix, let macerate for 14 days, and filter.

VI.

Essence of lemon 1 3/4 ounces

Rectified spirit of wine 6 ounces

Pure glycerine 3 ounces

Pure phosphate calcium 4 ounces

Distilled water to make 1 pint.

Mix essence of lemon, spirit of wine, glycerine, and 8 ounces of distilled water, agitate briskly in a quart bottle for 10 minutes, and introduce phosphate of calcium and again shake. Put in a filter and let it pass through twice. Digest in filtrate for 2 or 3 days, add 1 1/2 ounces fresh lemon peel, and again filter.

VII.

Oil of lemon 6 parts

Lemon peel (freshly grated) 4 parts

Alcohol, sufficient.

Dissolve the oil of lemon in 90 parts of alcohol, add the lemon peel, and macerate for 24 hours. Filter through paper, adding through the filter enough alcohol to make the filtrate weigh 100 parts.

VIII.

Exterior rind of lemon 2 ounces

Alcohol, 95 per cent, deodorized 32 ounces

Oil of lemon, recent 3 fluidounces

Expose the lemon rind to the air until perfectly dry, then bruise in a wedgwood mortar, and add it to the alcohol, agitating until the color is extracted; then add the lemon oil.

Natural Lemon Juice.

I. Take 4.20 parts of crystallized citric acid; 2 parts essence of lemons; 3 parts of alcohol of 96 per cent; 1/2 part calcium carbonate;

50 1/20 parts sodium phosphate, and 1/200 part calcium citrate, and dissolve the whole in sufficient water to make 60 parts.

II. Squeeze out the lemon juice, strain it to get rid of the seeds and larger particles of pulp, etc., heat it to the boiling point, let it cool down, add talc, shake well together and filter. If it is to be kept a long time (as on a sea voyage) a little alcohol is added.

Lime juice. This may be clarified by heating it either alone or mixed with a small quantity of egg albumen, in a suitable vessel, without stirring, to. near the boiling point of water, until the impurities have coagulated and either risen to the top or sunk to the bottom. It is then filtered into clean bottles, which should be completely filled and closed (with pointed corks), so that each cork has to displace a portion of the liquid to be inserted. The bottles are sealed and kept at an even temperature (in a cellar). In this way the juice may be satisfactorily preserved.

Nutmeg Essence. Oil of nutmeg, 2 drachms; mace, in powder, 1 ounce; alcohol, 95 per cent, deodorized, 32 ounces.

Dissolve the oil in the alcohol by agitation, add the mace, agitate, then stopper tightly, and macerate 12 hours. Filter through paper.

Orange Extract. Grated peel of 24 oranges; alcohol, 1 quart; water, 1 quart; oil of orange, 4 drachms. Macerate the orange peel and oil of orange with alcohol for 2 weeks. Add distilled water and filter.

Orange Extract, Soluble.

I. Pure oil of orange, 1 1/4 fluidounces; carbonate of magnesium, 2 ounces; alcohol, 12 fluidounces; water, quantity sufficient to make 2 pints.

II. Dissolve oil of orange in the alcohol, and rub it with the carbonate of magnesium, in a mortar. Pour the mixture into a quart bottle, and fill the bottle with water. Allow to macerate for a week or more, shaking every day. Then filter through paper, adding enough water through the paper to make filtrate measure 2 pints.

Orange Peel, Soluble Extract.

Freshly grated orange rind 1 part

Deodorized alcohol 1 part

Macerate for 4 days and express. Add the expressed liquid to 10 per cent of its weight of powdered magnesium carbonate

[317]

ESSENCES AND EXTRACTS

in a mortar, and rub thoroughly until a smooth, creamy mixture results; then gradually add the water, constantly stirring. Let stand for 48 hours, then filter through paper. Keep in an amber bottle and cool place. To make syrup of orange, add 1 part of this extract to 7 parts of heavy simple syrup.

Peach Extract.

Linalyl formate 120 minims

Amyl valerianate 8 drachms

Fluid extract orris 2 ounces

Oenanthic ether 2 drachms

Oil rue (pure German) 30 minims

Chloroform 2 drachms

Glycerine 2 ounces

Alcohol, 70 per cent, to 3 pints.

Pineapple Essence. A ripe, but not too soft, pineapple, weighing about, say, 1 pound, is mashed up in a mortar with Tokay wine, 6 ounces. The mass is then brought into a flask with 1 pint of water, and allowed to stand 2 hours. Alcohol, 90 per cent, 3/4 pint, is then added and the mixture distilled until 7 quarts of distillate have been collected. Cognac, 9 ounces, is then added to the distillation.

Pistachio Essence.

I.

Essence of almond 2 fluidounces

Tincture of vanilla 4 fluidounces

Oil of neroli 1 drop

II.

Oil of orange peel 4 fluidrachms

Oil of cassia 1 fluidrachm

Oil of bitter almond 15 minims

Oil of calamus 15 minims

Oil of nutmeg 1 1/2 fluidrachms

Oil of clove 30 minims

Alcohol 12 fluidounces

Water 4 fluidounces

Magnesium carbonate 2 drachms

Shake together, allow to stand 24 hours, and filter.

Pomegranate Essence.

Oil of sweet orange 3 parts

Oil of cloves 3 parts

Tincture of vanilla 15 parts

Tincture of ginger 10 parts

Maraschino liqueur 150 parts

Tincture of coccionella 165 parts

Distilled water 150 parts

Phosphoric acid, dilute 45 parts

Alcohol, 95 per cent, quantity sufficient to make 1 000 parts.

Mix and dissolve.

Quince Extract.

Fluid extract orris 2 ounces

Oenanthic ether 1/2 ounces

Linalyl formate 90 minims

Glycerine 2 ounces

Alcohol, 70 per cent, to 3 pints.

Raspberry Syrup, without Alcohol or Antiseptics. The majority of producers of fruit juices are firmly convinced that the preservation of these juices without the addition of alcohol, salicylic acid, etc., is impossible. Herr Steiner's process to the contrary is here reproduced:

The fruit is crushed and pressed; the juice, with 2 per cent of sugar added, is poured into containers to about three-quarters of their capacity, and there allowed to ferment. The containers are stoppered with a cork through which runs a tube, whose open end is protected by a bit of gum tubing, the extremity of which is immersed in a glass filled with water. It should not go deeper than 4/10 of an inch high. The evolution of carbonic gas begins in about 4 hours and is so sharp that the point of the tube must not be immersed any deeper.

Ordinarily fermentation ceases on the tenth day, a fact that may be ascertained by shaking the container sharply, when, if it has ceased, no bubbles of gas will appear on the surface of the water.

The fermented juice is then filtered to get rid of the pectinic matters, yeast, etc., and the filtrate should be poured back on the filter several times. The juice filters quickly and comes off very clear. The necessary amount of sugar to make a syrup is now added to the liquid and allowed to dissolve gradually for 12 hours. At the end of this time the liquid is put on the fire and allowed to boil up at once, by which operation the solution of the sugar is made complete. Straining through a tin strainer and filling into heated bottles completes the process.

The addition of sugar to the freshly pressed juice has the advantage of causing the fermentation to progress to the full limit, and also to preserve, by the alcohol produced by fermentation, the beautiful red color of the juice.

Any fermentation that may be permitted prior to the pressing out of the juices is at the expense of aroma and flavor; but whether fermentation occurs before or after pressure of the berry, the ordinary alcohol test cannot determine whether the juice has been completely fermented (and consequently whether the pectins have been completely separated) or not. Since, in spite of the fact that the liquid remains limpid after 4 days'

[318]

ESSENCES AND EXTRACTS

fermentation, the production of alcohol is progressing all the time a demonstration that fermentation cannot then be completed, and that at least 10 days will be required for this purpose.

An abortive raspberry syrup is always due to an incomplete or faulty fermentation, for too often does it occur that incompletely fermented juices after a little time lose color and become turbid.

The habit of clarifying juices by shaking up with a bit of paper, talc, etc., or boiling with albumen is a useless waste of time and labor. By the process indicated the entire process of clarification occurs automatically, so to speak.

Deep Red Raspberry Syrup. A much deeper and richer color than that ordinarily attained may be secured by adding to crushed raspberries, before fermentation, small quantities of sugar, sifted over the surface in layers. The ethylic alcohol produced by fermentation in this manner aids in the extraction of the red coloring matter of the fruit. Moreover, the fermented juice should never be cooked over a fire, but by superheated steam. Only in this way can caramelization be completely avoided. Only sugar free from ultramarine and chalk should be used in making the syrup, as these impurities also have a bad influence on the color.

Raspberry Essences.

I.

Raspberries, fresh 16 ounces

Angelica (California) 6 fluidounces

Brandy (California) 6 ounces

Alcohol 6 ounces

Water, quantity sufficient.

Mash the berries to a pulp in a mortar or bowl, and transfer to a flask, along with the Angelica, brandy, alcohol, and about 8 ounces of water. Let macerate overnight, then distil off until 32 ounces have passed over. Color red. The addition of a trifle of essence of vanilla improves this essence.

II.

Fresh raspberries 200 grams

Water, distilled 100 grams

Vanilla essence 2 grams

Pulp the raspberries, let stand at a temperature of about 70º F. for 48 hours, and then add 100 grams of water. Fifty grams are then distilled off, and alcohol, 90 per cent, 25 grams, in which 0.01 vanillin has been previously dissolved, is added to the distillate.

Sarsaparilla, Soluble Extract.

Pure oil of wintergreen 5 fluidrachms

Pure oil of sassafras 5 fluidrachms

Pure oil of anise 5 fluidrachms

Carbonate of magnesium 2 1/2 ounces

Alcohol 1 pint

Water, quantity sufficient to make

2 pints.

Dissolve the various oils in the alcohol, and rub with carbonate of magnesium in a mortar. Pour the mixture into a quart bottle, and fill the bottle with water. Allow to macerate for a week or more, shaking every day. Then filter through the paper, adding enough water through the paper to make the finished product measure 2 pints.

Strawberry Juice. Put into the water bath 1,000 parts of distilled water and 600 parts of sugar and boil, with constant skimming, until no more scum arises. Add 5 parts of citric acid and continue the boiling until about 1,250 parts are left. Stir in, little by little, 500 parts of fresh strawberries, properly stemmed, and be particularly careful not to crush the fruit. When all the berries are added, cover the vessel, remove from the fire, put into a warm place and let stand, closely covered, for 3 hours, or until the mass has cooled down to the surrounding temperature, then strain off through flannel, being careful not to crush the berries. Prepare a sufficient number of pint bottles by filling them with warm water, putting them into a kettle of the same and heating them to boiling, then rapidly emptying and draining as quickly as possible. Into these pour the hot juice, cork and seal the bottles as rapidly as possible. Juice thus prepared retains all the aroma and flavor of the fresh berry, and if carefully corked and sealed up will retain its properties a year.

Strawberry Essence.

Strawberries, fresh 16 ounces

Angelica (California) 6 fluidounces

Brandy (California) 6 ounces

Alcohol 8 ounces

Water, quantity sufficient.

Mash the berries to a pulp in a mortar or bowl, and transfer to a flask, along with the Angelica, brandy, alcohol, and about 8 ounces of water. Let macerate overnight, then distil off until 32 ounces have passed over. Color strawberry red. The addition of a little essence of vanilla and a hint of lemon improves this essence.

[319]

ESSENCES AND EXTRACTS

Tea Extract

I.

Best Souchong tea 175 parts

Cinnamon 3 parts

Cloves 3 parts

Vanilla 1 part

Arrack 800 parts

Rum 200 parts

Coarsely powder the cinnamon, clove, etc., mix the ingredients, and let macerate for 3 days, then filter, press off, and make up to 1,000 parts, if necessary, by adding rum. The Souchong may be replaced by any other brand of tea, and the place of the arrack may be occupied by Santa Cruz, or New England rum. The addition of fluid extract of kola nut not only improves the taste, but gives the drink a remarkably stimulating property. The preparation makes a clear solution with either hot or cold water and keeps well.

II. Tea, any desirable variety, 16 ounces; glycerine, 4 ounces; hot water, 4 pints; water, sufficient to make 1 pint.

Reduce the tea to a powder, moisten with sufficient of the glycerine and alcohol mixed, with 4 ounces of water added, pack in percolator, and pour on the alcohol (diluted with glycerine and water) until 12 ounces of percolate have been obtained. Set this aside, and complete the percolation with the hot water. When this has passed through, evaporate to 4 ounces, and add it to the percolate first obtained.

Tonka Extract.

Tonka beans 1 ounce

Magnesium carbonate, quantity sufficient.

Balsam of Peru 2 drachms

Sugar 4 ounces

Alcohol 8 ounces

Water sufficient to make 16 ounces. Mix the tonka, balsam of Peru, and

magnesia, and rub together, gradually adding the sugar until a homogeneous powder is obtained. Pack in a percolator; mix the alcohol with an equal amount of water, and pour over the powder, close the exit of the percolator, and let macerate for 24 to 36 hours, then open the percolator, and let pass through, gradually adding water until 16 ounces pass through.

Vanilla Extracts.

I. Vanilla, in fine bits, 250 parts, is put into 1,350 parts of mixture, of 2,500 parts 95 per cent alcohol, and 1,500 parts distilled water. Cover tightly, put on the water bath, and digest for 1 hour, at 140º F. Pour off the liquid and set aside. To the residue in the bath, add half the remaining water, and treat in the same manner. Pack the vanilla in an extraction apparatus, and treat with 250 parts of alcohol and water, mixed in the same proportions as before. Mix the results of the three infusions first made, filter, and wash the filter paper with the results of the percolation, allowing the filtered percolate to mingle with the filtrate of the mixed infusions.

II. Take 60 parts of the best vanilla beans, cut into little pieces, and put into a deep vessel, wrapped with a cloth to retain the heat as long as possible. Shake over the vanilla 1 part of potassium carbonate in powder, and immediately add 240 parts distilled water, in an active state of ebullition. Cover the vessel closely, set aside until it is completely cold, and then add 720 parts alcohol. Cover closely, and set aside in a moderately warm place for 15 days, when the liquid is strained off, the residue pressed, and the whole colate filtered.

The addition of 1 part musk to the vanilla before pouring on the hot water improves this essence.