The

Science Notebook

Lionel Chem-Lab

- Chapter 24

The

Science Notebook

Lionel Chem-Lab

- Chapter 24

NOTE: This book was published in 1942 as a manual to

accompany several Lionel Chemistry sets of the time. While

some of the experiments and activities here may be safely

done as written, a number of them use chemicals and methods no

longer considered safe. In addition, much of the

information contained in this book about chemistry and other

subjects is outdated and some of it is inaccurate.

Therefore, this book is probably best appreciated for its

historical value rather than as a source for current information

and good experiments. If you try

anything here, please understand that you do so at your

own risk. See our Terms of Use.

Pages 244 - 255

CHAPTER XXIV

OTHER INDUSTRIES

GLUE, CEMENT AND MUCILAGE

An adhesive

is a sticky substance, such as glue or mucilage, which can be

applied to a surface and cause it to adhere to another surface. Dextrin (obtained from

starch) and gum arabic

are used to manufacture the gum used on envelopes and stamps.

There are several types of glue all of which are

derivatives of vegetable and animal matter. Fish glue is made from

refuse fish stock. Animal and bone glues come from bones, hoofs

and horns. The process of manufacture consists of boiling the

matter after it has been chemically softened by an alkali, then

drying the resulting solution.

Billboard posters are applied with a starch paste.

EXPERIMENT No. 631 Preparation Of Starch Paste

(CL-44, CL-55, CL-66, CL-77)

APPARATUS:

Calcium chloride, powdered starch, test tube, alcohol lamp or

candle.

PROCEDURE:

Place twelve measures of powdered starch in a test tube one quarter

filled with water and shake thoroughly. Put two measures of calcium

chloride in another test tube half full of boiling water. Add the

starch solution and let it boil for a few more minutes, then cool

it. This will make a very good starch paste which you can preserve,

if you wish, by adding a few drops of carbolic acid.

EXPERIMENT No. 632 Preparation Of Flour Paste

(CL-33, CL-44, CL-55, CL-66, CL-77)

APPARATUS:

Calcium chloride and white flour.

PROCEDURE:

Mix ten measures of white flour and three measures of calcium

chloride in a test tube. Fill the tube half full of water and boil

for a few minutes. Discontinue heating as soon as the mixture forms

a paste. Preserve by adding a few drops of carbolic acid. This

is the kind of paste that paper hangers use.

EXPERIMENT No. 633 A Cement For Blue China

(CL-66, CL-77)

APPARATUS:

Sodium silicate solution, copper sulfate, mortar and pestle, pieces

of blue china.

244

LIONEL

CHEM-LAB 245

PROCEDURE:

Put two measures of copper sulfate in your mortar. Mix in a few

drops of sodium silicate solution to make a paste. Apply an even

coat to both surfaces of the china pieces. Set aside to harden.

EXPERIMENT No. 634 A Cement For White China And

Porcelain

(CL-66, CL-77)

APPARATUS:

Calcium carbonate, sodium silicate solution, mortar and pestle,

pieces of white china or porcelain.

PROCEDURE:

Place two measures of calcium carbonate in your mortar. Add a few

drops of sodium silicate solution and mix well to make a paste.

Apply a line coat of cement to both surfaces of the china or

porcelain pieces and press them together tightly. Clean off any

excess cement and allow to harden for a day or two.

EXPERIMENT No. 635 A Cement to Mend Metal Vessels

(CL-66, CL-77)

APPARATUS:

Powdered iron, ammonium chloride, sulfur, mortar and pestle, a leaky

metal container.

PROCEDURE:

Put two measures of sulfur, ten measures of powdered iron and two

measures of ammonium chloride in your mortar. Add several drops of

water, enough to form a thick paste. Press the paste firmly over the

opening or crack in the vessel. Allow to stand for a day. Heat the

vessel over a stove for a few moments.

EXPERIMENT No. 636 How “Rubber Cement” Is Made

(CL-66, CL-77)

APPARATUS:

Carbon tetrachloride, rubber scraps, test tube and cork or cotton.

PROCEDURE:

Put into a dry test tube a few small pieces of scrap photo engravers

to cement paper and cardboard together because it Close the test

tube with your thumb and shake vigorously. Stopper the tube with a

cork or wad of cotton and set aside, occasionally shaking the tube.

Note in due time the resulting thick substance.

SUMMARY:

Rubber cement is used by artists, photographers and photo-engravers

to cement paper and cardboard together because it does not wrinkle

or leave any stains. Using a dry lump of the material like an

eraser, you can completely clean any surplus cement from around the

edges of the job.

EXPERIMENT No. 637 Sodium Silicate Cement

(CL-11, CL-22, CL-33, CL-44, CL-55, CL-66, CL-77)

APPARATUS:

Sodium silicate solution, two small pieces of broken glass, a small

brush and a small piece of cloth.

PROCEDURE:

Apply a thin film of sodium silicate solution to the edges of the

glass. Allow to dry for a few seconds, then press the,

246 OTHER

INDUSTRIES

pieces tightly together. Clean off the excess with a damp cloth and

allow to harden for at least one day. In addition to cementing

broken glass, sodium silicate can also be used to cement paper and

cardboard.

EXPERIMENT No. 638 Making Glue From Lime And

Egg-white

(CL-66, CL-77)

APPARATUS:

Two pieces of broken crockery, egg, mortar and pestle, and calcium

oxide.

PROCEDURE:

Place a small amount of egg-white in your mortar. Add a sufficient

quantity of calcium oxide to make a substantial paste. Apply quickly

to the edges of the broken crockery and press tightly together. Note

how quickly the cement hardens.

EXPERIMENT No. 639 How To Make Mucilage From Gum

Arabic

(CL-44, CL-55, CL-66, CL-77)

APPARATUS:

Gum arabic, test tube, alcohol lamp or candle.

PROCEDURE:

Place six measures of gum arabic in a test tube half full of water

and allow to stand overnight. Heat contents carefully until the gum

arabic dissolves completely. Note the adhesive properties of gum

arabic. Preserve if necessary by adding a few drops of carbolic

acid.

EXPERIMENT No. 640 Preparation Of Postage Stamp

Mucilage

(CL-44, CL-55, CL-66, CL-77)

APPARATUS:

Gum arabic, sugar, starch, test tube, piece of paper, brush, candle

or alcohol lamp.

PROCEDURE:

Place two measures of gum arabic, eight measures of sugar and two

measures of starch in a test tube half full of water. Allow the

mixture to stand for several hours. Boil for a few minutes and then

allow to cool. Apply with a brush to a piece of paper and allow to

dry. Moisten mucilage as you would a postage stamp when ready to

attach to some surface. This mucilage is similar to that used by our

government in making postage stamps.

TANNING AND THE LEATHER INDUSTRY

Leather is made from the skins of various

animals by the process known as tanning.

This process consists of first removing the hair by the use of

lime, then washing with a weak acid. Tannic acid, or tannin, obtained from the bark of the hemlock

tree and other woods is then applied to change the skin slowly

into leather.

EXPERIMENT No. 641 How To Make Nickel Tannate

(CL-66, CL-77)

LIONEL

CHEM-LAB 247

APPARATUS:

Nickel chloride, tannic acid and test tubes.

PROCEDURE:

Dissolve one measure of tannic acid in a test tube one quarter full

of water. Dissolve one measure of nickel chloride in another test

tube containing the same amount of water. Add tannic acid solution

and note the pale green precipitate. This precipitate is nickel

tannate.

EXPERIMENT No. 642 How To Make Molybdenum Tannate

(CL-77)

Repeat Experiment No. 641 substituting ammonium molybdate for nickel

chloride. Ammonium molybdate in the presence of tannic acid forms a

rust colored solution.

EXPERIMENT No. 643 How To Make Tungsten Tannate

(CL-77)

Repeat Experiment No. 641 substituting one half measure of sodium

tungstate for nickel chloride. The yellow precipitate will be

tungsten tannate.

EXPERIMENT No. 644 How Copper Tannate Is Formed

(CL-55, CL-66, CL-77)

Repeat Experiment No. 641 substituting copper sulfate for nickel

chloride. The precipitate will be copper tannate.

EXPERIMENT No. 645 How Ferric Tannate Is Formed

(CL-11, CL•22, CL-33, CL-44, CL-55, CL-66, CL-77)

Repeat Experiment No. 641 substituting ferric ammonium sulfate for

nickel chloride. The ferric breaks away from the ammonium sulfate

and unites with the tannic acid to form the black precipitate of

ferric tannate.

EXPERIMENT No. 646 How To Make Ferrous Tannate

(CL-55, CL-66, CL-77)

Repeat Experiment No. 641 substituting ferrous ammonium sulfate for

nickel chloride. The greenish black precipitate will be ferrous

tannate.

EXPERIMENT No. 647 Formation Or Chromium Tannate

(CL-44, CL-55, CL-66, CL-77)

Repeat Experiment No. 641 substituting chrome alum for nickel

chloride. The green precipitate will be chromium tannate.

248 OTHER

INDUSTRIES

EXPERIMENT No. 648 Formation Of Cobalt Tannate

(CL-33, CL-44, CL-55, CL-66, CL-77)

Repeat Experiment No. 641 substituting cobalt chloride for nickel

chloride. The pink precipitate will be cobalt tannate.

EXPERIMENT No. 649 How Hemlock Bark Is Tested For

Tannic Acid

(CL-11, CL-22, CL-33, CL-44, CL-55, CL-66, CL-77)

APPARATUS:

Hemlock bark, ferric ammonium sulfate, two test tubes, alcohol lamp

or candle.

PROCEDURE:

Boil two small pieces of hemlock bark for five minutes in a test

tube half full of water. Pour off the clear liquid into another test

tube. Add a quarter measure of ferric ammonium sulfate. Note the

black color.

SUMMARY:

The black precipitate indicates the presence of tannic acid in the

bark.

EXPERIMENT No. 650 Tannic Acid In Tea

(CL-11, CL-22, CL-33, CL-44, CL-55, CL-66, CL-77)

APPARATUS:

Tea leaves, two test tubes, ferric ammonium sulfate, alcohol lamp or

candle.

PROCEDURE:

Boil two measures of tea leaves in a test tube one quarter full of

water. Pour off the clear liquid into another test tube. Add a

quarter measure of ferric ammonium sulfate and note the reaction.

EXPERIMENT No. 651 How To Test Chestnut Bark For

Tannic Acid

(CL-11, CL-22, CL-33, CL-44, CL-55, CL-66, CL-77)

APPARATUS:

Ferric ammonium sulfate, two test tubes, candle or alcohol lamp,

chestnut bark.

PROCEDURE:

Boil two measures of chestnut bark in a test tube half full of

water. Pour the liquid into another test tube. Add a quarter measure

of ferric ammonium sulfate and note that the same reaction occurs as

in the preceding experiment.

EXPERIMENT No. 652 How To Test Sumac Wood For

Tannic Acid

(CL-11, CL-22, CL-33, CL-44, CL-55, CL-66, CL-77)

Repeat Experiment No. 651 substituting a small piece of sumac wood

for chestnut bark. Inasmuch as sumac wood also contains tannic acid,

the reaction will be a black precipitate.

EXPERIMENT No. 653 How To Test Oak For Tannic

Acid

(CL-11, CL-22, CL-33, CL-44, CL-55, CL-66, CL-77)

Repeat Experiment No. 651 substituting oak bark for chestnut bark.

This bark also contains tannic acid, the reaction will be a black

precipitate.

LIONEL

CHEM-LAB 249

EXPERIMENT No. 654 How Persimmon Is Tested For

Tannic Acid

(CL-11, CL-22, CL-33, CL-44, CL-55, CL-66, CL-77)

Repeat Experiment No. 651 substituting green persimmon for chestnut

bark. Persimmon contains tannic acid, the reaction will be a black

precipitate.

EXPERIMENT No. 655 Tannic Acid And Albumen

(CL-11, CL-22, CL-33, CL-44, CL-55, CL-66, CL-77)

APPARATUS:

Tannic acid, albumen (white of egg), and two test tubes.

PROCEDURE:

Add a few drops of albumen to a test tube half full of water.

Dissolve one measure of tannic acid in another test tube half full

of water. Slowly add this solution to the albumen solution and note

the precipitate. Skins contain albumen which reacts with tannic acid

to make a durable leather.

BLUEPRINTING

Blueprinting is the process by which an

original pen or pencil drawing made on translucent paper can be

reproduced merely by exposing the original over a specially

sensitized paper to a strong light.

After exposure, the print is developed by

dipping it into water and the portion of the blueprint paper

exposed to the light becomes dark blue, while the unexposed

portion (the part directly under the black lines on the original)

becomes white due to the action of the water on the chemical. This

gives a copy, consisting of a white line on a blue background,

exactly corresponding to the original.

EXPERIMENT No. 656 Making A Blueprint

(CL-11, CL-22, CL-33, CL-44, CL-55, CL-66, CL-77)

APPARATUS:

Blueprint paper (store), tracing paper or small flat key, paper

clip.

PROCEDURE:

Place a key (or a piece of tracing paper on which something has been

drawn with black ink) against the sheet of blueprint paper. Hold

tightly against the blueprint paper with a paper clip. Expose this

paper to bright sunlight for several minutes. Remove the original

and dip the blueprint into water. Allow to dry and note the result.

SUMMARY:

The silhouette of the key or the drawing is printed on the blueprint

paper. The light has not been able to penetrate through the key or

the lines on the drawing but has affected the blueprint paper not

covered by them. The exposed portion of the print paper becomes blue

while the unaffected portion remains white because the water washes

away the chemical on the unexposed areas.

250 OTHER

INDUSTRIES

PHOTOGRAPHY

There are two main steps in making a

photograph: (1) making the negative and (2) making the print.

To make a negative, you must first expose a

sensitized film (or glass plate) to light, then develop it in a

dark room, and finally "fix" the resulting negative so that

additional light rays do not affect it.

Photographic film is coated with silver

bromide. Exposing a film to the light, therefore, starts the reduction of the silver

bromide. A mild reducing agent as a developer continues the reduction process begun

by the action of the light.

Sodium thiosulfate, or "hypo" used as a fixer,

dissolves the unchanged silver salt so the film does not darken

again when exposed to the light.

A print is made from a negative film simply by

exposing some sensitized paper so that the light rays must first

pass through the film to reach the paper which is then developed

and fixed in the same way as the film.

EXPERIMENT No. 657 How A Photographic Print Is

Made

(CL-11, CL-22, CL-33, CL-44, CL-55, CL-66, CL-77)

APPARATUS:

Proof paper (photographic supply store), negative, glass, a green

light bulb.

PROCEDURE:

Perform the following experiment in a room illuminated only by a dim

green light. Place the dull surface of the negative, against the

sensitized surface of the proof paper which should be a little

larger than the negative. Place on a smooth surface with the

negative uppermost and cover with a sheet of clean glass. Expose to

strong sunlight until the paper projecting beyond the edge of the

negative turns dark brown. Remove the glass and separate the

negative from the proof paper. Examine the print.

SUMMARY:

The photographic print on the paper was produced by the

decomposition of silver halide which reacts and becomes black when

exposed to light. However, the paper will become completely black

after a time unless it is "fixed" in a bath of sodium thiosulfate.

EXPERIMENT No. 658 “Fixing” A Photographic Print

With “Hypo”

(CL-33, CL-44, CL-55, CL-66, CL-77)

APPARATUS:

Sodium thiosulfate, beaker or glass, stirring rod, a shallow pan.

PROCEDURE:

Dissolve fifteen measures of sodium thiosulfate in a glass or beaker

with a half inch of water. This solution is commonly called "hypo".

Dip the photographic print made in the preceding experiment into the

hypo solution for five minutes. Wash the print for several minutes

in a steady stream of running water. Dry the print thoroughly by

pressing it between blotters for an hour or more. Light has no

effect on a print after a “hypo" bath.

LIONEL

CHEM-LAB 251

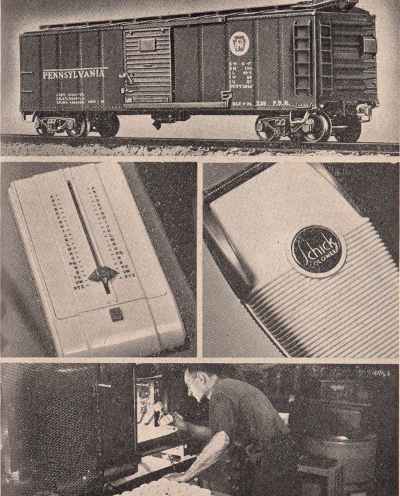

The upper

photos show three of the many thousands of articles made today

of molded plastics. That box car is not a real freight car at

all, but a very accurate Lionel scale model, the body of which

is entirely molded of Bakelite. The two other molded articles

are a telephone index and an electric razor. The lower photo

shows a scene in the General Electric plastics department where

ring boxes are being molded by the injection process.

252 OTHER

INDUSTRIES

EXPERIMENT No. 659 How A Photograph Is Made

(CL-11, CL-22, CL-33, CL-44, CL-55, CL-66, CL-77)

APPARATUS:

Sulfur, calcium oxide, test tube, candle or alcohol lamp, saucer,

photographic print.

PROCEDURE:

Put one measure of sulfur and one measure of calcium oxide into a

test tube half full of water. Boil for a few minutes, then pour the

solution into a saucer or pan. Dip a photographic print into the pan

and allow it to stand for about thirty minutes. Remove the print and

wash thoroughly under running water.

SUMMARY:

This process converts the silver to silver sulfide which imparts a

reddish-brown color to the print.

PLASTICS

In the ordinary sense "plastic" means “capable

of being molded or modeled, as clay," and, no doubt, the earliest

plastic material was the primitive potter’s clay. Broadly

speaking, rubber, clay, glass, Portland cement, and other

materials may be classified as plastics. However, the term "modern

plastics" is generally applied to a group of synthetic organic

materials which are made plastic by the use of heat and are

capable of being molded or pressed into finished parts and

products.

RUBBER

One of the most important materials supplied

to us by nature is rubber,

sometimes called "black gold" because of its commercial value.

First brought to the attention of the civilized world by Columbus,

who found the natives of Haiti playing with a rubber ball, this

material is now used for literally thousands of purposes and is

the basis of an industry which does a billion-dollar business

annually.

While hundreds of different trees, weeds and

vines contain rubber, none equals in quality and quantity that

obtained from the milky juice of the Hevea tree, native to the

equatorial jungles of Brazil. However, 96% of our supplies of

crude rubber come from the East Indies where the British and Dutch

have transplanted and cultivated the seed of the wild Brazilian

trees.

Rubber trees are tapped to obtain the “milk",

or latex, which flows from the trees and is collected in cups and

buckets much as maple syrup is collected. The rubber particles in

the latex can then be separated from the liquid by the use of

acetic acid. This causes the rubber to coagulate. Another method,

sometimes used, is to separate the rubber by evaporating off the

water. Chemicals such as zinc oxide, sulfur and carbon are next

compounded to this raw rubber, to make it suitable for ordinary

purposes. Adding the sulfur was the invention of Goodyear who

found that this

LIONEL

CHEM-LAB 253

treatment prevented the rubber from being

sticky and easily affected by the temperature. The name given to

this process is vulcanization.

NEOPRENE

Chemists throughout the world during the past fifty years have spent

many millions of dollars trying to make synthetic rubber. Although

they have not succeeded in the commercial manufacture of a product

identical with "real" rubber, in many respects they have done

better. Using four of nature’s own raw materials, limestone, coal,

salt and water, chemists are 1ow making a product known as neoprene

which looks like rubber, acts like rubber, and can be used in the

manufacture of practically all articles for which rubber is now

used.

254 OTHER

INDUSTRIES

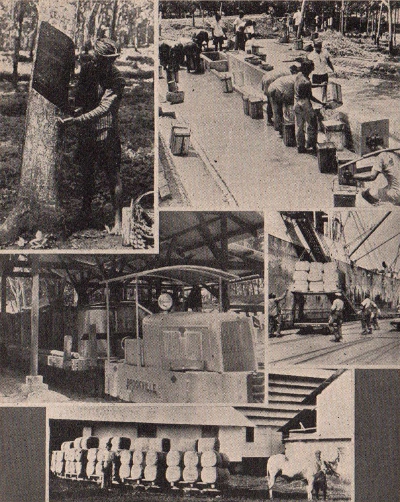

Goodyear

Rubber Company - These photos show how rubber is obtained

beginning with the tapping of the tree to obtain latex,

subsequent processing operations on the rubber plantation and

Finally loading the crude rubber at a deep seas harbor for

transportation to foreign ports.

LIONEL

CHEM-LAB 255

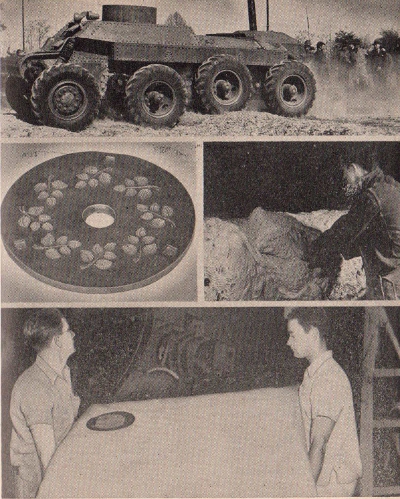

Two of

the reasons why Uncle Sam’s military machine needs vast

quantities of rubber are shown in the top and bottom

photographs. The upper photo shows one of the new style

"trackless" tanks undergoing tests while the lower photo is of a

bullet-sealing airplane gasoline tank. Photo left center shows a

new type of rubber mold used making costume jewelry. On right is

a picture of the mill used for washing Neoprene, synthetic

rubber.

"The Science Notebook"

Copyright 2008-2018 - Norman Young

The

Science Notebook

The

Science Notebook The

Science Notebook

The

Science Notebook