The

Science Notebook

Lionel Chem-Lab

- Chapter 7

The

Science Notebook

Lionel Chem-Lab

- Chapter 7

NOTE: This book was published in 1942 as a manual to

accompany several Lionel Chemistry sets of the time. While

some of the experiments and activities here may be safely

done as written, a number of them use chemicals and methods no

longer considered safe. In addition, much of the

information contained in this book about chemistry and other

subjects is outdated and some of it is inaccurate.

Therefore, this book is probably best appreciated for its

historical value rather than as a source for current information

and good experiments. If you try

anything here, please understand that you do so at your

own risk. See our Terms of Use.

Pages 112 - 120

CHAPTER VII

SILICON AND THE SILICATES

Of the three most important elements in nature,

everyone agrees that oxygen and carbon, because of their

prevalence and importance, rank first and second. And a chemist

would quickly tell you that the third ranking is silicon because

of its importance in the solid structure of the earth. Silicon

itself makes up at least 25% of the earth’s substances while its

compounds comprise at least 87%.

Pure silicon is not found free in nature but

occurs chiefly in the form of silicon dioxide, otherwise known as

silica, or sand and sandstone. In crystalline forms, it exists as

amethyst, rose quartz, smoky quartz, onyx, opal, agate and flint.

EXPERIMENT No. 201 Sodium Silicate Or "Water

Glass"

(CL-11, CL-22, CL-33, CL-44, CL-55, CL-66, CL-77)

APPARATUS:

Sodium silicate solution, paper, splints of wood, red litmus paper

and a small soft brush.

PROCEDURE:

Using a brush, paint some sodium silicate solution on a sheet of

paper. Allow paper to dry for fifteen minutes. Note the glassy film.

Place some silicate solution on a match stick and hold it against

another match stick. Let the sticks dry and then try to separate

them. Insert a piece of red litmus paper into the solution and note

the color change.

SUMMARY:

Sodium silicate is often used as an adhesive and to give a glazed

appearance to pottery. Sodium silicate turns red litmus paper blue

because it is made from a weak acid (silicic acid) and a strong base

(sodium hydroxide).

EXPERIMENT No. 202 Silicic Acid

(CL-11, CL-22, CL-33, CL-44, CL-55, CL-66, CL-77)

APPARATUS:

Sodium silicate solution, sodium bisulfate and test tubes.

PROCEDURE:

Pour some sodium silicate solution in a test tube one quarter filled

with water and shake well. Dissolve three measures of sodium

bisulfate in a test tube one quarter filled with water. Add to this

the sodium silicate solution and note the jelly-like precipitate.

Allow to stand for a few minutes and note that the precipitate

solidifies. The jellied precipitate is silicic acid.

112

LIONEL

CHEM-LAB 113

EXPERIMENT No. 203 Silicon Dioxide

(CL-44, CL-55, CL-66, CL-77)

APPARATUS:

Sodium silicate solution, sodium bisulfate, test tubes, stirring

rod, heating spoon and alcohol lamp.

PROCEDURE:

Pour a little sodium silicate solution in a test tube one-quarter

filled with water and shake test tube well. Dissolve three measures

of sodium bisulfate in another test tube one-quarter filled with

water. Add to this the sodium silicate solution and note the

jelly-like precipitate. Allow to stand for a while and observe that

the precipitate solidifies as silicic acid. Place some of this

precipitate in the measuring spoon and heat it over a flame for five

minutes. Note that the silicic acid precipitate dries into a white

solid.

SUMMARY:

When silicic acid is heated it loses water and becomes silicon

dioxide (sand).

Compounds consisting of silicon and one of the

elements are called silicides

of which the most important is carbon

silicate, or carborundum. After carbon and sand are

heated in an electric furnace and silicon is formed, under the

proper conditions silicon will combine with carbon to form

carborundum, an extremely hard substance, second only to the

diamond in its degree of hardness.

EXPERIMENT No. 204 Cobalt Silicate

(CL-33, CL-44, CL-55, CL-66, CL-77)

APPARATUS:

Cobalt chloride, sodium silicate solution and test tube.

PROCEDURE:

Place two measures of cobalt chloride in a test tube half-filled

with water. Shake to dissolve. To this solution, add a few drops of

sodium silicate and note the blue precipitate.

SUMMARY:

The cobalt reacts with the silicate to form the blue precipitate.

EXPERIMENT No. 205 Strontium Silicate

(CL-33, CL-44, CL-55. CL-66, CL-77)

Repeat Experiment No. 204 substituting strontium chloride for cobalt

chloride. The precipitate will be strontium silicate.

EXPERIMENT No. 206 Manganese Silicate

(CL-33, CL-44, CL-55, CL-66, CL-77)

Repeat Experiment No. 204 substituting manganese sulfate for cobalt

chloride. The precipitate will be manganese silicate.

EXPERIMENT No. 207 Magnesium Silicate

(CL-66, CL-77)

Repeat Experiment No. 204 substituting magnesium sulfate for cobalt

chloride. The precipitate will be magnesium silicate.

114 SILICON

AND THE SILICATES

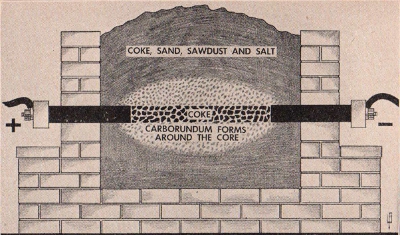

A

cross-section diagram of an electric furnace used in

manufacturing carborundum. The process consists of passing a

strong electric current through a mixture of sand, sawdust, coke

and salt.

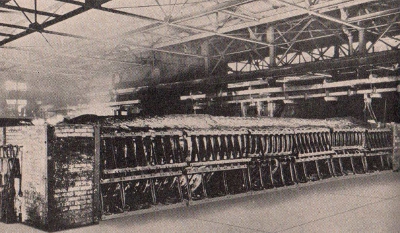

Photograph

of an electric carborundum furnace used by the Carborundum

Company.

LIONEL

CHEM-LAB 115

EXPERIMENT No. 208 Ferric Silicate

(CL-11, CL-22, CL-33, CL-44, CL-55, CL-66, CL-77)

Repeat Experiment No. 204 substituting ferric ammonium sulfate for

cobalt chloride. The precipitate will be ferric silicate.

EXPERIMENT No. 209 Ferrous Silicate

(CL-55, CL-66, CL-77)

Repeat Experiment No. 204 substituting ferrous ammonium sulfate for

cobalt chloride. The precipitate will be ferrous silicate.

EXPERIMENT No. 210 Copper Silicate

(CL-55, CL-66, CL-77)

Repeat Experiment No. 204 substituting copper sulfate for cobalt

chloride. The precipitate will be copper silicate.

EXPERIMENT No. 211 Chromium Silicate

(CL-44, CL-55, CL-66, CL-77)

Repeat Experiment No. 204 substituting chrome alum for cobalt

chloride. The precipitate will be chromium silicate.

EXPERIMENT No. 212 Aluminum Silicate

(CL-33, CL-44, CL-55, CL-66, CL-77)

Repeat Experiment No. 204 substituting aluminum sulfate for cobalt

chloride. The precipitate will be aluminum silicate.

EXPERIMENT No. 213 Calcium Silicate

(CL-33, CL-44, CL-55, CL-66, CL-77)

Repeat Experiment No. 204 substituting calcium chloride for cobalt

chloride. The precipitate will be calcium silicate.

EXPERIMENT No. 214 Tin Silicate

(CL-11, CL-22, CL-33, CL-44, CL-55, CL-66, CL-77)

APPARATUS:

Sodium bisulfate, ammonium chloride, tin metal (tin can), sodium

silicate solution and test tubes.

PROCEDURE:

Place a small piece of tin metal, two measures of sodium bisulfate

and two measures of ammonium chloride in a test tube. Add a few

drops of water and boil for a few minutes. Stop heating and pour off

the clear solution into another test tube to which more water is

added up to the one quarter mark. Add a few drops of sodium silicate

solution and note the thick white precipitate.

SUMMARY:

The dissolved tin reacts with the sodium silicate to form the thick,

milky precipitate of tin silicate.

EXPERIMENT No. 215 Zinc Silicate

(CL-44, CL-55, CL-66, CL-77)

116 SILICON

AND THE SILICATES

APPARATUS:

Zinc metal, sodium bisulfate, test tubes, alcohol lamp or candle,

sodium silicate solution.

PROCEDURE:

Put a small piece of zinc and four measures of sodium bisulfate in a

test tube. Add water up to the half-way mark. Heat until a little of

the zinc dissolves. Allow tube and contents to cool by immersing in

a glass of cold water. Add to the test tube a few drops of sodium

silicate solution and note the greyish-white precipitate.

SUMMARY:

The dissolved zinc reacts with the sodium silicate to form the

heavy, greyish-white precipitate of zinc silicate.

EXPERIMENT No. 216 Vegetation In A Drinking Glass

(CL-55, CL-66, CL-77)

APPARATUS:

Sodium silicate solution, copper sulfate, ferric ammonium sulfate,

cobalt chloride, chrome alum, calcium chloride, manganese sulfate,

tumbler and stirring rod.

PROCEDURE:

Pour two spoonfuls of sodium silicate solution into a tumbler one

quarter filled with water and stir thoroughly. Add to this a few

crystals of ferric ammonium sulfate, cobalt chloride, chrome alum,

calcium chloride, copper sulfate and a pinch of manganese sulfate.

Allow the glass to remain undisturbed for a few hours and note the

growth.

SUMMARY:

The crystals grow like plants and make a beautiful sight with the

formation of many colors.

The silicate industries include those

manufacturing glass, cement, brick, tile, pottery and chinaware.

To make glass, a silicate mixture is prepared

by melting certain metal compounds with sand at an extreme

temperature. This mixture is then completely melted and cooled

without crystallization. Because of the tendency of glass to be

very soft and plastic when in the cooling state, it can be molded

or blown in the glass factory to practically any desired shape and

size. Your Chem-Lab bottle, for example, was molded. In the

molding process, glass is forced into a cavity corresponding in

shape and size to the desired article. After a little molten glass

has been introduced to the mold, compressed air is blown in which

forces the glass outward so that it assumes the form and shape of

the mold. The article is then cooled, the mold opened, and the

finished pieces removed. The excess material around the top of the

bottle is removed and the sharp edges rounded off in a flame. Most

bottles are made today by automatic machinery.

Window glass used to be made from cylinders of

glass blown by skilled glass blowers, but mechanical operations

have almost entirely superseded this method. The molten glass is

now rolled between hot rollers and large, flat sheets are thus

made. Plate glass, on the other hand, is cast into large flat

slabs which, after grinding and polishing, have perfectly plane

surfaces.

LIONEL

CHEM-LAB 117

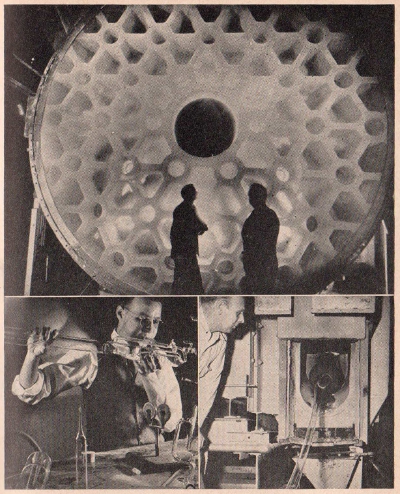

Top

photograph shows the great 200-inch mirror made by the Corning

Glass Works for the Mount Palomar Observatory. It is the largest

single piece of glass ever poured.

Lower

left shows a glass blower at work.

Lower right

shows silicate-glass tubing for fluorescent lamps pouring from a

General Electric Company furnace.

118 SILICON

AND THE SILICATES

EXPERIMENT N0. 217 Soft Glass

(CL-44, CL-55, CL-66, CL-77)

APPARATUS:

Sodium silicate solution, sodium carbonate, calcium oxide, alcohol

lamp, heating spoon, blowpipe.

PROCEDURE:

Pour five or six drops of sodium silicate solution in a heating

spoon. Add one measure of sodium carbonate and a half-measure of

calcium oxide. Mix the contents thoroughly. Direct the flame of the

alcohol lamp at this with the blowpipe, and note how it swells,

eventually becoming shiny and glassy.

SUMMARY:

Soft glass is commercially used for making bottles and drinking

glasses.

EXPERIMENT No. 218 Why Soft Glass Cracks Easily

(CL-11, CL-22, CL-33, CL-44, CL-55, CL-66, CL-77)

APPARATUS:

Glass tubing, alcohol lamp or candle, a glass.

PROCEDURE:

Heat a small piece of glass tubing. Immerse quickly in a glass of

water. Note that the tube cracks immediately.

SUMMARY:

Soft glass will crack if cooled quickly because the outside of the

glass is cooled more rapidly than the inside which sets up a strain.

EXPERIMENT No. 219 How To Make Hard Glass

(CL-44, CL-55, CL-66, CL-77)

APPARATUS:

Sodium silicate solution, sodium carbonate, calcium oxide, borax,

heating spoon, alcohol lamp, blowpipe.

PROCEDURE:

Mix a half measure of sodium carbonate, a half measure of calcium

hydroxide and one measure of borax with eight drops of sodium

silicate solution. Place the mixture on the heating spoon and heat

it by directing the flame of the alcohol lamp at the mixture with

the blowpipe. Note that the mixture froths for a while and

eventually melts into a clear, glassy bead.

SUMMARY:

Borax is one of the materials which can be added to glass enabling

it to withstand sudden changes in temperature without cracking.

EXPERIMENT No. 220 How To Frost Glass

(CL-66, CL-77)

APPARATUS:

Magnesium sulfate, liquid glue and a glass.

PROCEDURE:

Dissolve four teaspoonfuls of magnesium sulfate in a glass of water.

Add a teaspoonful of liquid glue and stir. Apply this to the object

to be frosted and set aside to dry.

SUMMARY:

Note the frosted appearance.

LIONEL

CHEM-LAB 119

EXPERIMENT No. 221 Etching Glass

(CL-11, CL-22, CL-33, CL-44, CL-55, CL-66, CL-77)

APPARATUS:

Glass, tumbler, strong liquid glue and small brush.

PROCEDURE:

Spread some heavy liquid glue on the outside and inside surfaces of

a glass tumbler. Set the tumbler aside to dry for a day and then

place it near a stove for another day. Move the tumbler to a cool

place and note that after awhile the glue begins to crack and chip

off. Allow it to remain in this cool spot for a short time and then

wash it with warm water to remove all the glue.

SUMMARY:

Note the etched surface caused by the cracking of the dried glue.

The liquid glue attacked the silicate in the glass and when the glue

was dried and began to chip off, some chips of glass came off with

the glue.

There are so many varieties and colors of

glass, you may wonder how they are made. Sometimes, merely by

adding a chemical, marvelous changes rake place. For example,

Pyrex glass which is used to make our Chem-Lab beakers and

Erlenmeyer flasks is able to stand sudden changes of temperature

and is not easily broken because sodium aluminum borosilicate was

added to the sand to make it especially resistant. Optical glass

gets its brilliancy because lead silicate is used. Colored glass

is made in dozens of shades by adding such chemicals as cobalt

compounds for blue, gold for ruby red, and manganese for purple.

EXPERIMENT No. 222 Making Light Green Glass

(CL-55, CL-66, CL-77)

APPARATUS:

Sodium silicate solution, sodium carbonate, calcium oxide, ferrous

ammonium sulfate, alcohol lamp, heating spoon, blowpipe.

PROCEDURE:

Mix on a clean sheet of paper one measure of sodium carbonate, one

third measure of calcium oxide and a very small crystal of ferrous

ammonium sulfate. Place the mixture in your heating spoon, add five

drops of sodium silicate and stir contents with stirring rod. Use

your alcohol lamp and blowpipe to play the flame directly on the

mixture. Note the changes as the heating continues.

SUMMARY:

The green color of the glass is produced by ferrous ammonium

sulfate.

EXPERIMENT No. 223 Making Amber Glass

(CL-44, CL-55, CL-66, CL-77)

Repeat Experiment No. 222 substituting one half measure of powdered

charcoal for the ferrous ammonium sulfate.

EXPERIMENT No. 224 Making Dark Blue Glass

(CL-44, CL-55, CL-66, CL-77)

Repeat Experiment No. 222 substituting one crystal of cobalt

chloride for the ferrous ammonium sulfate.

120 SILICON

AND THE SILICATES

HOW TO WORK GLASS TUBING

The glass tubing supplied

in Lionel Chem-Lab sets is "soft" glass, melting at

quite a low temperature. Because you will need to construct

certain simple laboratory apparatus to perform some of the

experiments, you will have to know how to cut glass tubing, bend

it and smooth its sharp edges.

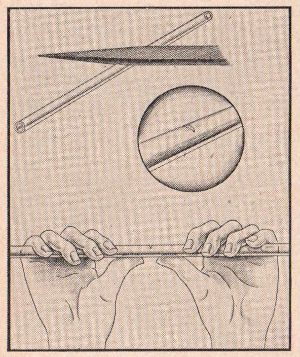

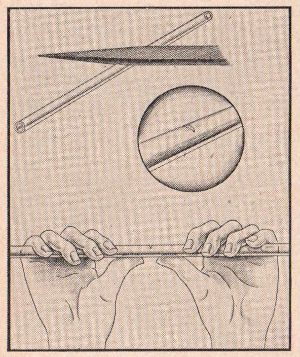

FIGURE 17

It is very easy to cut a piece of glass tubing

if you have a three-cornered file. Merely make a little scratch on

the glass with the file at the point where you wish to break the

tubing. Then grasp the tubing firmly with both hands, using your

thumbs as a fulcrum, and give it a sharp snap.

To smooth the sharp edges at the point of the

break, merely hold the end of the tube in the flame of your

alcohol lamp and rotate the tubing with your fingers. When the

glass gets hot enough it will begin to melt slightly which will

smooth the edges. This is sometimes called "fire-polishing".

To bend a piece of glass tubing, hold it in the

flame until the glass gets red hot at the point where you wish to

make the bend. Rotate the tube rapidly in your fingers so that

this section gets uniformly hot. You will feel and notice the

softening of the glass. When red hot, remove from the flame and

bend to the desired angle. Be careful, however, of heating until

it gets too soft otherwise the sides of the tubing will melt

together and close up the hole in the center.

It is also easy to make a tube with a nozzle,

such as an eyedropper. Cut off a section of glass tubing and hold

it in the flame until red hot, but instead if making the bend as

described in the preceding paragraph, stretch the tubing out until

it becomes very thin in the middle. Remove from the flame and make

a file cut at the place where the glass has the proper taper for

your particular purpose. Break off the extra piece of glass and

you will have the desired nozzle.

"The Science Notebook"

Copyright 2008-2018 - Norman Young

The

Science Notebook

The

Science Notebook The

Science Notebook

The

Science Notebook