The

Science Notebook

Lionel Chem-Lab

- Chapter 15

The

Science Notebook

Lionel Chem-Lab

- Chapter 15

NOTE: This book was published in 1942 as a manual to

accompany several Lionel Chemistry sets of the time. While

some of the experiments and activities here may be safely

done as written, a number of them use chemicals and methods no

longer considered safe. In addition, much of the

information contained in this book about chemistry and other

subjects is outdated and some of it is inaccurate.

Therefore, this book is probably best appreciated for its

historical value rather than as a source for current information

and good experiments. If you try

anything here, please understand that you do so at your

own risk. See our Terms of Use.

Pages 183 - 190

CHAPTER XV

THE STORY OF IRON AND STEEL

Iron has been known and widely used as a metal

for over four thousand years. Its greatest use today is in the

manufacture of steel, an alloy of iron and carbon capable of being

hardened, toughened and otherwise altered by suitable heat

treatment. With the exception of the meteorites which fall to the

earth, iron does not occur free in nature. However, the ores of

iron are very abundant and the metal is easily produced from them.

The foremost iron ores are magnetite,

hematite, limonite and a carbonate

known as siderite.

Pure iron has very few uses and is rarely

produced. When other elements such as carbon are added, even in

small percentages, the properties of iron are considerably changed

and it becomes much more useful.

Cast iron

is made by mixing iron ore with a suitable flux and reducing it by

heating with coke. This operation is carried out in a large tower

eighty feet high and twenty feet in diameter, known as a blast furnace.

STEEL

Steel is made from cast iron by burning out a

part of the carbon, silicon, phosphorous and sulfur. The chief

processes for doing this are the Bessemer Process and the Open-Hearth Process.

When the manufacture of steel is finished, the

molten metal is poured into molds for castings, or cast into

ingots to be forged into bars, rails, and other suitable forms for

commercial and industrial purposes.

The alloy steels have other elements than

carbon added in proper percentages to give them exceptional

qualities of hardness and toughness. The chief elements used in

these alloying processes are chromium, cobalt, tungsten,

molybdenum, manganese and nickel.

Nickel steels are the most important alloy

steels. Adding chromium to the extent of 12% or 13% makes steel

completely rust-proof. It is then commercially known as stainless steel.

EXPERIMENT No. 427 Ferrous Hydroxide

(CL-55, GL-66, GL-77)

APPARATUS:

Ferrous ammonium sulfate, sodium carbonate, calcium oxide, test tube

and alcohol lamp or candle.

PROCEDURE:

Prepare some sodium hydroxide solution as explained in Experiment

No. 344. Dissolve one measure of ferrous ammonium

183

184 IRON

AND STEEL

sulfate in a test tube half full of water. Add a few drops of sodium

hydroxide and note the green precipitate of ferrous hydroxide which

darkens upon standing.

EXPERIMENT No. 428 Another Way To Make

Ferrous Hydroxide

(CL-77)

APPARATUS:

Ferrous ammonium sulfate, ammonium hydroxide, test tube.

PROCEDURE:

Dissolve one half measure of ferrous ammonium sulfate in a test tube

half full of water. Add a few drops of ammonium hydroxide. Note the

dark green precipitate of ferrous hydroxide.

EXPERIMENT No. 429 Ferrous Ammonium Molybdate

(CL-77)

APPARATUS:

Ammonium molybdate, ferrous ammonium sulfate and test tubes.

PROCEDURE:

Dissolve one half measure of ammonium molybdate in a test tube

containing one inch of water. Dissolve one measure of ferrous

ammonium sulfate in another test tube half full of water. Add

some ammonium molybdate to the ferrous ammonium sulfate solution.

The brown-black precipitate is ferrous ammonium molybdate.

EXPERIMENT No. 430 Ferrous Ammonium Molybdate

Dissolved

(CL-77)

APPARATUS:

Ammonium molybdate, ferrous ammonium sulfate, test tubes,

hydrochloric acid.

PROCEDURE:

Prepare ferrous ammonium molybdate as described in the preceding

experiment. Add five drops of hydrochloric acid to the precipitate.

Note how the precipitate dissolves and the resulting color.

EXPERIMENT No. 431 Preparing Ferrous Chromate

(CL-77)

APPARATUS:

Sodium chromate, ferrous ammonium sulfate and test tubes.

PROCEDURE:

Dissolve one half measure of sodium chromate in a test tube one

quarter full of water. Dissolve one measure of ferrous ammonium

sulfate in another test tube half full of water. Mix the two

solutions. The orange-brown precipitate is ferrous chromate.

EXPERIMENT No. 432 Dissolving Ferrous Chromate

(CL-77)

APPARATUS:

Sodium chromate, hydrochloric acid, ferrous ammonium sulfate and

test tubes.

PROCEDURE:

Dissolve a half measure of sodium chromate in a test

LIONEL

CHEM-LAB 185

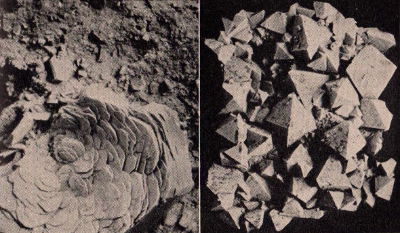

U.

S. National Museum

An

illustration of two of the variety of forms in which iron ore

occurs. The photograph on the left shows the hexagonal crystals

of hematite while the one on the right shows the rhombic

crystals of Swiss magnetite.

tube one quarter full of water. Dissolve one measure of ferrous

ammonium sulfate in another test tube half full of water. Mix the

two solutions. An orange-brown precipitate of ferrous chromate is

formed. Now add a few drops of hydrochloric acid and the precipitate

will dissolve because a soluble salt was formed.

EXPERIMENT No. 433 How To Make Ferrous Sulfide

(CL-77)

APPARATUS:

Ammonium hydroxide, ferrous ammonium sulfate, paraffin, sulfur,

candle or alcohol lamp.

PROCEDURE:

Prepare some hydrogen sulfide as described in Experiment No. 233.

Dissolve one measure of ferrous ammonium sulfate in a test tube half

full of water. Pass some hydrogen sulfide gas into the above

solution. Note that a black precipitate of ferrous sulfide is formed

which, upon exposure to air, oxidizes and converts the ferrous

sulfide into ferric sulfide, a brown precipitate.

EXPERIMENT No. 434 How To Make Ferrous Salicylate

(CL-55, CL-66, CL-77)

APPARATUS:

Ferrous ammonium sulfate, sodium salicylate, test tubes.

PROCEDURE:

Dissolve one measure of ferrous ammonium sulfate in a test tube

containing one inch of water. Dissolve one measure of sodium

salicylate in another test tube containing the same amount of

186 IRON AND STEEL

water. Mix the two solutions to obtain ferrous salicylate, a

rust-colored solution.

EXPERIMENT No. 435 How To Make Ferrous Tungstate

(CL-77)

APPARATUS:

Ferrous ammonium sulfate, sodium tungstate, test tubes.

PROCEDURE:

Dissolve one measure of ferrous ammonium sulfate in a test tube half

full of water. Dissolve one half measure of sodium tungstate in

another test tube one quarter full of water. Mix the two solutions.

The light-brown precipitate is ferrous tungstate.

EXPERIMENT No. 436 Oxidizing Ferrous Hydroxide

(CL-77)

APPARATUS:

Ammonium hydroxide, hydrogen peroxide (drug store), ferrous ammonium

sulfate and test tubes.

PROCEDURE:

Prepare a precipitate of ferrous hydroxide by using the ammonium

hydroxide reagent. (Experiment No. 428). Add exactly three drops of

hydrogen peroxide. Note the color change in the precipitate.

SUMMARY:

Hydrogen peroxide, a fairly strong oxidizing agent when added to a

ferrous salt, oxidizes it to the ferric state, and the color changes

from green to reddish-brown.

EXPERIMENT No. 437 Reducing Ferric To Ferrous

Chloride

(CL-66, CL-77)

APPARATUS:

Ferric chloride, ferrous ammonium sulfate, hydrochloric acid, zinc,

gas generator bottle, alcohol lamp or candle, test tubes.

PROCEDURE:

Dissolve one measure of ferric chloride in a test tube containing

one inch of water. Prepare some hydrogen gas as described in

Experiment No. 72. Bubble some gas into the above solution and note

that hydrogen is capable of reducing ferric to ferrous chloride.

EXPERIMENT No. 438 Ferric Chloride And Ammonium

Hydroxide

(01.-66, cL-77)

APPARATUS:

Ferric chloride, ammonium hydroxide and test tubes.

PROCEDURE:

Dissolve one measure of ferric chloride in a test tube one quarter

full of water. Add a few drops of ammonium hydroxide.

SUMMARY:

Ferric chloride reacts with ammonium hydroxide to form ammonium

chloride and ferric hydroxide (reddish-brown precipitate).

EXPERIMENT No. 439 Slow Oxidation Of Iron Pyrites

(CL-66, CL-77)

APPARATUS:

Iron pyrites, blue litmus paper, saucer.

LIONEL

CHEM-LAB 187

PROCEDURE:

Pour just enough water into a saucer to cover three measures of iron

pyrites. Set aside for a few days. Dip piece of blue litmus paper

into the water. Note the change in color.

SUMMARY:

Blue litmus paper changes in color due to the formation of hydrogen

sulfide - the iron being slowly oxidized to iron oxide by oxygen in

the water.

EXPERIMENT No. 440 Ferric Hydroxide

(CL-11, CL-22, CL-33, CL-44, CL-55, CL-66, CL-77)

APPARATUS:

Ferric ammonium sulfate, sodium carbonate, calcium oxide, alcohol

lamp or candle and test tubes.

PROCEDURE:

Prepare some sodium hydroxide solution as explained in Experiment

No. 344. Dissolve two measures of ferric ammonium sulfate in a test

tube half full of water. Add a few drops of sodium hydroxide

solution. The reddish-brown precipitate, which is similar to iron

rust, is ferric hydroxide.

EXPERIMENT No. 441 Dissolving Ferric Hydroxide

(CL-77)

APPARATUS:

Hydrochloric acid, ferric chloride, ammonium hydroxide and test

tubes.

PROCEDURE:

Dissolve one measure of ferric chloride in a test tube one quarter

full of water. Add a few drops of ammonium hydroxide to obtain a

reddish-brown precipitate. Add a few drops of hydrochloric acid.

Note how the precipitate dissolves in an acid solution proving that

ferric hydroxide is soluble in acids.

EXPERIMENT N0. 442 Transforming Ferric Hydroxide

(CL-77)

APPARATUS:

Ferric chloride, ammonium hydroxide, test tubes, alcohol lamp.

PROCEDURE:

Prepare a precipitate of ferric hydroxide as described in Experiment

No. 440. Heat precipitate thoroughly for about five minutes. Note

the color formation of the solid. This is ferric oxide known as

rouge in the cosmetics industry.

EXPERIMENT No. 443 How To Make Ferric Tungstate

(CL-77)

APPARATUS:

Sodium tungstate, ferric chloride and test tubes.

PROCEDURE:

Dissolve one measure of ferric chloride in a test tube half full of

water. Add one measure of sodium tungstate to another test tube

containing the same amount of water. Add one half the amount of

sodium tungstate solution to the ferric chloride solution. The pale

yellow precipitate is ferric tungstate.

188 IRON

AND STEEL

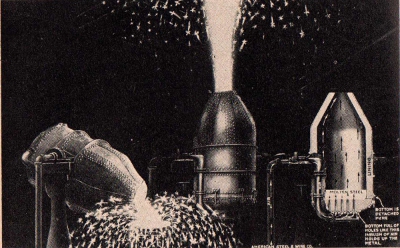

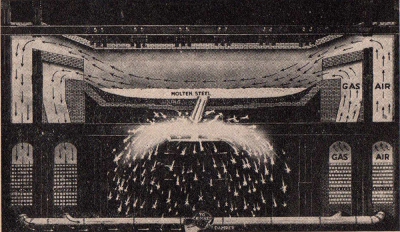

In the

Bessemer process of steel-making, a. blast of compressed air is

forced through molten pig iron to convert it into steel.

Ore of

less purity than that used in the Bessemer process is

successfully made into fine steel by the Open Hearth process.

LIONEL

CHEM-LAB 189

EXPERIMENT No. 444 Preparation Ferric Chromate

(CL-77)

APPARATUS:

Ferric chloride, sodium chromate and test tubes.

PROCEDURE:

Dissolve one half measure of sodium chromate in a test tube one

quarter full of water. Dissolve one measure of ferric chloride in

another test tube half full of water. Mix the two solutions. The

pale yellow precipitate is ferric chromate, soluble in hydrochloric

acid.

EXPERIMENT N0. 445 How To Make Ferric Salicylate

(CL-66, CL-77)

Repeat Experiment No. 444 substituting sodium salicylate for sodium

chromate. The purple precipitate will be ferric salicylate.

EXPERIMENT No. 446 Preparation Of Ferric

Phosphate

(CL-66, GL-77)

Repeat Experiment No. 444 substituting trisodium phosphate for

sodium chromate. The yellowish-white precipitate will be ferric

phosphate.

EXPERIMENT No. 447 Preparation Of Ferric Acetate

(CL-66, CL-77)

APPARATUS:

Calcium oxide, sodium carbonate, acetic acid, ferric chloride and

test tubes.

PROCEDURE:

Prepare a solution of sodium hydroxide as described in Experiment

No. 344. Filter solution in a clean test tube and add one quarter

test tube of acetic acid solution. Shake the test tube thoroughly.

Dissolve one measure of ferric chloride in another test tube. Add

some acetate solution to the ferric chloride solution.

SUMMARY:

A reddish-brown color is formed. This color is attributed to the

formation of the complex salt of ferric acetate.

EXPERIMENT No. 448 How Ferric Carbonate Is Made

(CL-66, CL-77)

Repeat Experiment No. 44-44 substituting sodium carbonate for sodium

chromate. The yellow-orange precipitate will be ferric carbonate.

EXPERIMENT No. 449 Ferric Molybdate

{CL-77)

Repeat Experiment No. 444 substituting ammonium molybdate for sodium

chromate. The pale yellow precipitate will be ferric molybdate.

EXPERIMENT N0. 450 Converting A Yellow

Precipitate

(CL-77)

APPARATUS:

Ferric chloride, ammonium molybdate, hydrochloric acid and test

tubes.

190 IRON

AND STEEL

PROCEDURE:

Prepare a precipitate of ferric molybdate explained in the preceding

experiment. Add four drops of hydrochloric acid to the precipitate.

Note how the precipitate dissolves forming a light yellow-green

solution.

EXPERIMENT No. 451 Free Carbon Present In Cast

Iron

(CL-22, CL~33, CL-44, CL-55, CL-66, CL-77)

APPARATUS:

Powdered iron, sodium bisulfate, test tube, candle or alcohol lamp.

PROCEDURE:

Put one measure of powdered iron and five measures of sodium

bisulfate in a test tube. Pour water up to the one third mark and

heat gently to dissolve the sodium bisulfate. Note the bubbling

reaction and the odor.

SUMMARY:

Carbon in the iron is oxidized to carbon dioxide gas. The odor is

hydrogen sulfide.

EXPERIMENT No. 452 Preparing A Colored Solution

(CL-66, CL-77)

APPARATUS:

Ferric carbonate, sodium carbonate, hydrochloric acid and test

tubes.

PROCEDURE:

Prepare a precipitate of ferric carbonate as described in Experiment

No. 448. Add a few drops of hydrochloric acid to the precipitate.

Note how the precipitate dissolves forming a canary-yellow solution.

EXPERIMENT No. 453 Decomposition Of Ferric

Thiosulfate

(CL-33, CL-44, CL-55, CL-66, CL-77)

APPARATUS:

Sodium thiosulfate, ferric ammonium sulfate, two test tubes.

PROCEDURE:

Dissolve three measures of sodium thiosulfate in a test tube half

full of water. Dissolve one measure of ferric ammonium sulfate in

another test tube half full of water. Pour a few drops into the

sodium thiosulfate solution and note the dark red color. Allow to

stand and observe how the color gradually fades.

SUMMARY:

On standing the ferric is reduced to ferrous tetrathionate, a

colorless solution.

"The Science Notebook"

Copyright 2008-2018 - Norman Young

The

Science Notebook

The

Science Notebook The

Science Notebook

The

Science Notebook