The

Science Notebook

Lionel Chem-Lab

- Chapter 22

The

Science Notebook

Lionel Chem-Lab

- Chapter 22

NOTE: This book was published in 1942 as a manual to

accompany several Lionel Chemistry sets of the time. While

some of the experiments and activities here may be safely

done as written, a number of them use chemicals and methods no

longer considered safe. In addition, much of the

information contained in this book about chemistry and other

subjects is outdated and some of it is inaccurate.

Therefore, this book is probably best appreciated for its

historical value rather than as a source for current information

and good experiments. If you try

anything here, please understand that you do so at your

own risk. See our Terms of Use.

Pages 229 - 234

CHAPTER XXII

TEXTILES AND PAPER

Carbohydrate

is the name applied to a group of carbon compounds which includes

sugars, starches and cellulose. These compounds

all contain carbon, hydrogen and oxygen, the last two being

present in the ratio of two to one, just as in water. Cellulose

having the formula C6H10O5 is an

example of the relationship.

All plants, wood and vegetable fibers contain

cellulose either free or combined. Cotton and linen are nearly

pure cellulose. Paper, another common cellulose product, is

manufactured from wood pulp or rags. Cellulose can be separated

from wood and vegetable fibers by a strong base or acid.

There are various grades and qualities of paper

ranging from cheap, porous substances, such as newsprint, to fine

stationery and bonds made from rags. Newsprint is made primarily

from spruce wood pulp. All papers, whether made from wood pulp or

rags, are essentially cellulose derivatives.

EXPERIMENT No. 583 How Rag Paper Is Made

(CL-66, CL-77)

APPARATUS:

Sodium carbonate, calcium oxide, test tube, mortar and pestle, bits

of rag, alcohol lamp or candle.

PROCEDURE:

Put a few small pieces of rag in a test tube. Add four measures of

sodium carbonate and three measures of calcium oxide. Add water

until the test tube is three quarters full, then carefully boil for

a few minutes, taking care not to spill the liquid. Transfer

contents to the mortar and grind well until a pulp is formed. Rinse

the pulp by pouring off the old water and adding new water. Remove

as much water as possible and set the pulp aside to dry. This

process is similar to that used in making rag-content writing paper.

EXPERIMENT No. 584 How Wood Pulp Paper Is Made

(CL-66, CL-77)

APPARATUS:

Sodium bisulfate, match, mortar and pestle, test tube, alcohol lamp

or candle and a dish.

PROCEDURE:

Carefully whittle live or six match sticks (without heads) and four

measures of sodium bisulfate into your mortar. Grind the shavings

with the pestle until they are reduced to shreds. Place the contents

in a test tube one third full of water and boil for

229

230

TEXTILES AND PAPER

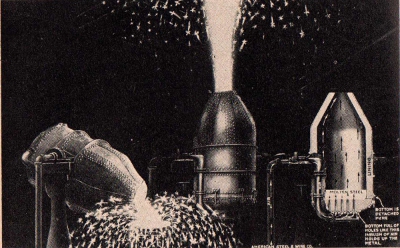

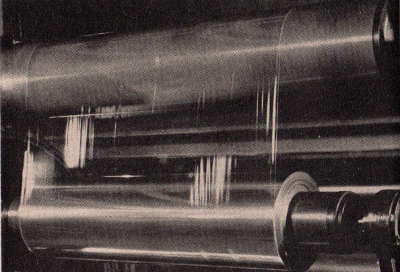

du Pont

The upper

photograph shows a shredding machine in which sheets of wood

pulp are shredded after having been treated with a solution of

caustic soda. This is the first step toward the production of

finished "Cellophane" which is shown in the lower picture being

wound on cores at tremendous speed.

LIONEL

CHEM-LAB 231

five minutes, taking care not to let the liquid spill over. Transfer

the contents of the tube to the mortar and grind well until a pulp

is formed. Rinse the pulp by pouring off the old water and adding

new water. Remove as much water as possible and place the pulp on a

dish to dry. Examine it carefully. This material will closely

resemble the pulp used in making newsprint.

EXPERIMENT No. 585 Testing Paper For Starch

(CL-44, CL-55, CL-66, GL-77)

APPARATUS:

Ferric ammonium sulfate, sodium bisulfate, sodium iodide solution,

paper and test tube.

PROCEDURE:

Dissolve one measure of ferric ammonium sulfate and one measure of

sodium bisulfate in a test tube half full of water. Add two drops of

sodium iodide solution and shake well. Note the orange-brown color.

Apply a little of this solution to a sheet of paper. Reverse the

paper and note if a blue stain appears. The starch test can be used

to prove that paper contains starch.

CELLOPHANE

Cellophane and rayon are similar in that both

are made from cellulose. In the case of rayon, a cellulose

solution is forced through microscopic holes into a chemical bath

which changes the tiny streams of “liquid cellulose" back into

filaments of solid cellulose. In the manufacture of cellophane,

the viscose solution is forced out into the chemical bath through

a long narrow slit and the result is a thin film of cellulose.

TEXTILE FIBERS

Cotton and linen yarns, composed principally

of cellulose, have a vegetable source, but wool and silk yarns are

made from animal fibers. Vegetable and animal fibers look very

much alike at first glance, but by feeling them, examining them

closely, applying certain chemical tests to them, or looking at

the fibers under a microscope, certain essential differences in

the structure and shape of the fiber soon appear. These are

natural textile fibers. In the last few years, chemistry has

developed a whole group of new synthetic materials, such as rayon

and nylon, which have completely revolutionized the textile and

garment industry and have supplanted the natural fibers in many

articles of clothing.

EXPERIMENT No. 586 Odor Test For Vegetable Fibers

(CL-11, CL-22, CL-33, CL-44, CL-55, CL-66, CL-77)

APPARATUS:

Vegetable fibers (cotton or linen), candle or alcohol lamp.

PROCEDURE:

Burn the vegetable fibers over the candle. Note the

232

TEXTILES AND PAPER

faint odor, similar to burning paper. Note how these fibers burn

rapidly leaving white ashes. White ashes and the odor of burning

paper are characteristics of burning vegetable fibers.

EXPERIMENT No. 587 How Cloth Is Tested For Animal

Fibers

(CL-11, CL-22, CL-33, CL-44, CL-55, CL-66, CL-77)

APPARATUS:

Silk and wool, candle or alcohol lamp.

PROCEDURE:

Burn first some silk then some wool fibers. Note the peculiar odor

similar to that of burning hair. Notice how long the fibers burn and

also the ball of carbon which remains. A burned hair odor is a test

for animal fibers.

EXPERIMENT No. 588 A Test For Rayon

(CL-11, CL-22, CL-33, CL-44, CL-55, CL-66, CL-77)

APPARATUS:

Piece of rayon cloth, candle or alcohol lamp.

PROCEDURE:

Unravel some fibers from a piece of rayon and burn them. Note the

presence of any odor.

SUMMARY:

Rayon made from an acetic acid compound will possibly give a

slightly irritating sensation to your nose when burned.

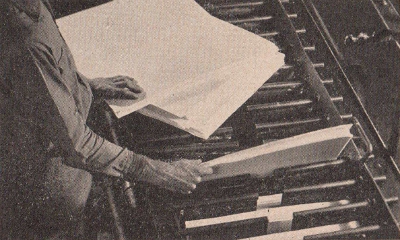

The first

step in the manufacture of rayon. The operator is shown here

loading a steeping press with sheets made of cotton linters and

wood pulp.

LIONEL

CHEM-LAB 233

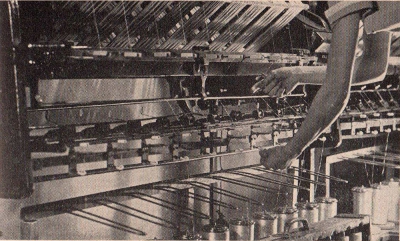

A du Pont rayon reeling

machine. The operator is drawing rayon threads through guides so

they may be wound into skeins on the spindles below.

EXPERIMENT No. 589 How Fabrics Are Tested For

Pure Linen Fibers

(CL-55, CL-66, CL-77)

APPARATUS:

Sodium bisulfate, glycerine, test tube, linen, candle or alcohol

lamp and two blotters.

PROCEDURE:

Dissolve one half measure of sodium bisulfate in a test tube half

full of water. Drop a piece of linen into this solution, then boil

for a few minutes. Remove linen from test tube and wash thoroughly.

Set aside to dry. Expose the fibers by raveling the edges, then

dampen one corner with a drop of glycerine. Squeeze the cloth

between two blotters and place it against a dark background. Note

whether the saturated corner of the cloth is translucent. The purity

of linen is proved by its translucency.

EXPERIMENT No. 590 An Alkali Test For Animal

Fibers

(CL-11, GL-22, CL-33, CL-44, CL-55, CL-66, CL-77)

APPARATUS:

Calcium oxide, sodium carbonate and a few strands of white wool

yarn.

PROCEDURE:

Make some sodium hydroxide by dissolving two measures of calcium

oxide and two measures of sodium carbonate in a test tube half full

of water. Heat to boiling for a few minutes, insert the wool and

continue to boil for a few minutes longer. If the material

234

TEXTILES AND PAPER

dissolves completely, it is pure wool. Check this test by performing

the same experiment with some cotton fibers.

EXPERIMENT No. 591 Testing New Cotton Goods For

Starch

(CL-55, CL-66, CL-77)

APPARATUS:

Sodium bisulfate, ferric ammonium sulfate, sodium iodide solution,

two test tubes and cotton goods.

PROCEDURE:

Dissolve one measure of sodium bisulfate and one half measure of

ferric ammonium sulfate in a test tube half full of water. Add a

drop of sodium iodide solution. Put a small piece of cotton goods

into another test tube half full of water and boil for a few

minutes. Remove the cotton and allow the liquid to cool. Add two

drops of sodium iodide solution and note any change in color. If a

blue color forms, the material contains starch.

EXPERIMENT No. 592 Rejuvenating Old Silk

(CL-44, CL-55, CL-66, CL-77)

APPARATUS:

Small piece of old silk, acetic acid, glass, blotters.

PROCEDURE:

Pour a small quantity of acetic acid into a glass. Place the silk in

the acid and allow it to steep for five or ten minutes. Remove the

silk and place it between the blotters, squeezing out most of the

acid. Allow the silk to dry and then note how its luster and

characteristic rustle have been restored. Acetic acid is popular

with chemists for dissolving organic substances and in dilute form

it is frequently used by tailors and cleaners for restoring old

silks.

NYLON

Nylon should be considered not as a single

compound, nor as assuming any particular form, such as yarn.

Rather, nylon is the name of a family of materials, like wood,

steel, stone or glass, any one of which may take various forms.

Just as we have different kinds of glass, designed particularly

for windows, spectacle lenses, or cooking-vessels, so are there

many different types of nylon, each with its individual

properties. Think of a mysterious chemical family that can produce

monofilaments for brush bristles, surgical sutures and

fishing-leaders; fibers for sheer hosiery, dress goods, bathing

suits, draperies and upholstery; insulation for electrical wires;

and sheets rivaling leather in strength and toughness!

Nylon’s most extensive use now is in fine

hosiery. Because of the natural abundance of its basic ingredients

- coal, air and water - it promises to make the hosiery industry

less and less dependent on foreign raw materials.

"The Science Notebook"

Copyright 2008-2018 - Norman Young

The

Science Notebook

The

Science Notebook The

Science Notebook

The

Science Notebook